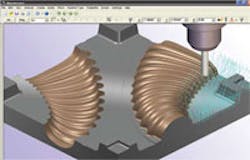

Computer Aided Manufacturing (CAM) software offers machine shop operators a fast return-on-investment productivity improvement solution, but finding the CAM package that offers a shop the most potential benefit is anything but easy.

Mergers, acquisitions and entries in the already dynamic CAM software market makes it even more difficult for machine shop operators to identify which CAM package is right for them.

There are more than 40 CAM software packages available, and more are introduced to the market each year.

Not all of those packages, however, are meant to be used by machine shops to cut metal. Some focus on metal stamping or bending, some are meant to be used in woodworking, and others to run robot and automated material handling.

The accompanying table includes the most widely used CAM packages for cutting metal. It is a guide that is designed to help narrow the list of candidates a shop should consider when it is looking at CAM packages. The features noted in the CLICK HERE TO ACCESS TABLE represent the general functions shops look for in a CAM package.

All of the information in the table comes from the software developers.

Functions that developers said are part of their software offering are marked with a “Y.” Functions that do not have a “Y” either are not a part of a particular package or the developer has not indicated that it is part of its package.

For shops that receive part models from outside sources, the ability to work with specific import formats without using translator software is a time saver, and therefore is a major factor when those shops consider CAM software.

If a machine shop uses a variety of machines such as mills, lathes, wire EDM and waterjets, the ability to use a single CAM package with all of those machines might be a deciding factor.

Some of the packages have some form of cut verification built into them, while others require the use of stand-alone verification programs such as Vericut or Predator to perform that function.

Software packages included in this table range from those that are relatively inexpensive and simple to use, such as AlphaCAM and BobCAD/CAM, to complex packages, such as Catia, that are meant to be used by many departments or suppliers of large companies.

No table can provide all, or even most, of the information that is needed to choose the package that is best for each shop. Many of the qualities a shop operator looks for in a CAM package cannot be reduced to a simple “yes, it’s there” or “no, it’s not,” and have to do with the look and feel of a program as much as its actual function. Critical analysis is needed to determine the best choice for a shop.

The most common reason that a shop uses a specific CAM package is that it was the software the machine tool supplier recommended or because it is the package the shop’s CNC programmer is familiar with.

Machine shops are in the business of cutting metal, not evaluating software, so it is impractical to expect each shop to do a detailed analysis of all CAM packages to find the best to suit its needs. Nor is it reasonable to expect the machine tool supplier to stay current with all of the developments in CAM software.

Because CAM software offers such a high return-on-investment, American Machinist decided to present a series of in-depth analyses of the CAM packages listed in the table.

Benchmark testing of the packages will use a set of parts that represents a range of machining challenges.

Qualitative analysis of the look, feel and ease of use of the package.

And, a composite of feedback from package users.

We intend for these analyses to be tools that machine shop owners and managers can use to better understand the choice of CAM software available to them.

We will present analyses beginning in the July issue of American Machinist.