Reducing setup times — the time it takes to prepare a job for machining— a common goal for most shops. Like other machining goals, reducing setup times takes time and therefore costs money. The most profitable, most productive shops usually operate with a mindset of continually improving their operations, and they also must constantly budget how and where they will spend time on improvements.

It is easy to reach a point of diminishing returns when trying to squeeze the last second or last nickel from an operation, and reducing setup times is no exception. To avoid going past that point and wasting more time than is saved, it is useful to start out with an expectation of just how much time can reasonably be taken out of the setup time for any given job.

Knowing in general what other top shops are achieving in reducing their setup times can give a shop a reasonable target for reducing their setup times. The 2006 American Machinist Benchmarking Survey provides that type of information.

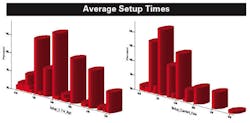

Respondents in the survey indicated what their setup time(in hours) is for an average job this year compared to what it was three years ago. The median value of all shops showed a 25 percent reduction to 1.5 hr today from 2.0 hr three years ago. Benchmark shops, the shops that are in the top 20 percent in terms of productivity and profit, reported a 54 percent decrease to 1.3 hours from 2.8 hours. Digging a little deeper, we found that 55 percent of all shops that provided setup time information reduced their setup times by 50 percent to 75 percent over the last three years.

Looking at actual hours, 83 percent of all reporting shops report current average setup times of 3.0 hr or less (see attached charts), compared with the 82 percent that reported average setup times of 5.0 hr or less three years ago.

Those numbers tell us that more than 80 percent of all shops have been able to reduce their average setup times by about 40 percent over the last three years. While the survey does not tell us is how those shops achieved those reductions, we can look at the tools and techniques that are used by the shops with the greatest setup time reductions (50 percent to 75 percent).

Sixty-two (62) percent of the ‘super-reducers' also focus on maximizing machine uptime. That compares with 45 percent of all shops that focus on machine uptime. Fifty-six (56) percent of the ‘super-reducers' also maximize machine cutting time, compared to only 47.1 percent of all shops. And, 59 percent use prefixturing workpieces and 49 percent use tooling presets compared with only 38 percent and 46 percent of all shops respectively.

The percentage of use of five-axis machining, multitasking, multiple spindle machines, cellular manufacturing, automation and robotics is about the same for the ‘super-reducers' as it is for all shops, making it statistically uncertain what impact those tools and techniques have on setup times.

Using the numbers from the survey as a benchmark, a shop that has not had an aggressive program of setup time reduction could reasonably seek a 50 percent to 75 percent reduction, but for shops that have been consistently reducing their setup times, such large reductions may be impossible or too costly to achieve.

| Committed to improving your shop operations? American Machinist's Machine Shop Workshop is November 7-9, 2007. Learn how to:

|