[IMTS] Renishaw's Lean-Design XL-80 Laser Calibration System

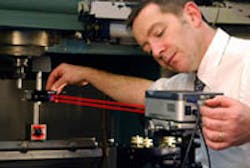

Renishaw advances technology in laser interferometer calibration with the "lean design" XL-80 system. The new design allows a 4X faster slew rate and a 10X higher dynamic data capture rate in a smaller, lighter and more portable package. The XL-80 brings nanometer-level motion analysis to calibration, error-mapping and compensation of everything from laboratory equipment, semi-conductor processing machinery and radio surgery tools to coordinate measuring machines, lithography equipment, advanced machine tools, robots, and assembly systems.

The XL-80 increases linear measurement speed to 4m/s while providing a resolution of 1 nm, even at top speed. Lightweight, compact packaging enables easier transport and set up, while a six-minute warm up minimizes waits to increase available measurement time. A new signal gain switch gives the option of 80 m linear range (such as for large aircraft profilers) or increased signal strength at shorter ranges and a system accuracy of .5 ppm is maintained over the full operating range of 0-40C.

The XL-80 takes readings at 50 kHZ, up from 5 kHZ for Renishaw's previous industry-standard ML10. The 10X increase in bandwidth enables capture of detailed data about small high frequency movements.

The new XL-80 system is backward compatible with optics from Renishaw's ML10 laser system.