Among the benefits to NCL users will be higher performance results with lower operating costs; shorter cycle times (“as much as 3 to 1, or more, over traditional milling”); reduced machine wear; and longer tool life.

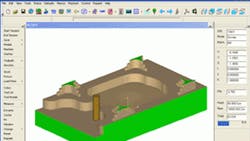

More specifically, the VoluMill engine will achieve efficient toolpaths for open shapes machined with NCL. The programmer can cut any combination of part/stock boundaries easily, NCCS stated, and all open edges are fully leveraged for efficient machining and to minimize plunging into the material.

Also, the CAM will determine “intelligent” options for slot milling and side milling. For softer metals, the software provides the fastest possible cycle time and intelligently selects slot milling or side milling to maximize the material removal rate. Feedrates and axial depths of cut are automatically adjusted in slot milling to maintain a constant material removal rate, and can be overridden by the programmer. For harder materials, users can require side milling over the entire tool path to avoid burying the cutter.

Next, it achieves fast machining of small pockets. The program offers the fastest way to clear out small pockets. In addition, offers efficient, specialized tool motion for tight spaces.

High-feed repositioning with floor clearance is possible with the VoluMill engine, as the software leverages the machine's capabilities more fully, so that the tool moves as safely and quickly as possible when not engaged in material. Additionally, it clears the floor by a small amount when repositioning at the highest possible speed, without dragging it across an already-machined floor.

Other advantages include cleanup milling — VoluMill makes it possible to use a small tool to cut material left by a larger tool in a previous operation — and automatic feedrate adjustment and optimization, which lets the programmer maintain a more consistent load on the cutting tool. No feedrate optimizer is needed.

"NCCS is dedicated to constantly improving our software technology, giving the end user what they want," stated president Don Schultz. "The combination of NCL and VoluMill is yet another example of the entrepreneurial spirit that has made the company successful."

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.