New Group Debuts EDM and Five-Axis Designs

UNITED GRINDING GROUP – which recently formed UNITED MACHINING SOLUTIONS following its takeover of GF Machining Solutions – will stage the North American debut of that brand next month at CMTS in Toronto. During that Sept. 29-Oct. 2 event, visitors can view and evaluate the Agie Charmilles CUT P 350 Pro wire EDM and the Mikron Mill E 700 U high-speed machining center.

The Agie Charmilles CUT P 350 Pro machine capitalizes on more than 70 years of electric discharge machining (EDM) technology. The CUT P 350 Pro is applicable to any application, with a robust design and the intuitive UNIQUA human/machine interface (HMI), as well as multiple automation options for “lights out” operation.

With Intelligent Power Generator (IPG) technology, the CUT P 350 Pro delivers surface finishes as smooth as Ra 0.08 µm and heightens accuracy with integrated thermal regulation that enables it to achieve an accuracy of ±2µm.

Linear scales and rotary encoders form a double measuring system that protects the X, Y, U, V, and Z axes. In the event of a collision, the system differentiates between the linear scales indicating no movement and the rotary encoder indicating movement, which then automatically stops the axes without damage to machine or workpiece.

In the Quadrax® mechanical design of the CUT P 350 Pro, the table and work tank remain stationary; therefore, the workpiece does not move, allowing for heavy workpieces. Independent U/V and X/Y axes with equal length (X = U travel; Y = V travel), lower mass and completely independent movement produce large, tapered cuts of 45 deg over the entire length in Z.

Additionally, a Rhenocast machine base offers lower thermal conductivity and vibration damping, helping to maintain high precision accuracy throughout the day.

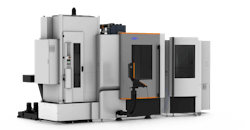

For high-speed, high-efficiency five-axis machining, the Mikron Mill E Series delivers quality parts and optimal chip removal. With a swivel range of -65 to +120 degrees and tables that accommodate loads up to 450 kg (992 lbs.), shops can machine a wide range of parts across automotive, energy, and general machinery markets.

The Mikron Mill E’s rigid, stable C-frame cast iron machine construction reduces vibrations to deliver high levels of precision and repeatability, while large guideways, double side-supported rotary tables and optimized chip evacuation enhance reliability and part quality. In addition, a powerful 20,000-rpm STEP-TEC spindle tackles both rough milling and drilling operations.

In addition to the Agie Charmilles and legacy United Grinding brand technologies, the new United Machining Group incorporates the Charmilles, Mikron Mill, Liechti, Step Tec, and System 3R brands, to offer comprehensive, integrated solutions for precision parts, tools, and molds. The portfolio includes milling, EDM, laser texturing, laser micromachining and additive manufacturing machines, as well as advanced spindles, automation, tooling, and digitalization solutions designed to boost productivity and efficiency.

Learn more at www.grinding.com/en