Taking Impossible Designs Into Real Prototypes

Machine programmers are constantly under pressure to improve the efficiency of their operations, but that demand is only a logical follow-up to the pressure on programmers to convert more unusual projects into set-ups that can be machined effectively and executed with profitability.

Jobs deemed impossible by many manufacturers are all in a day’s work at Cornerstone Prototype Development, a Pawtucket, Rhode Island fabricator that is confident it can accomplish what others cannot do. For general manager Craig Watkins, whose duties include engineering and programming, the only sure thing is that he’ll never be sure what types of jobs will come next.

“We do a lot of really exotic things that other shops don’t have the knowledge or software, or ability, to do. Everything that we do is different,” he said, “all of the time.”

Watkins took to engineering naturally as a child and today has nearly 20 years of experience in manufacturing, and for the past seven years at Cornerstone.

Established in 1996 and billed as a full-service design and fabrication outfit, Cornerstone builds prototypes for virtually any industry or product. Its mission is to “assist companies, inventors and designers in bringing their ideas into tangible concepts and functioning prototypes.”

“We typically sit down with clients to understand what they want to accomplish and where they are so far,” Watkins said. “It’s easy to make a rough prototype, but we want to create something with manufacturability in mind. If something has an electrical component, we want to make sure it’s capable of serving its purpose.”

In the cause of offering a roster of prototyping services, Cornerstone has capabilities for CNC machining, engineering, design, model-making, tooling, rapid prototyping, RTV molding, urethane casting, painting, sculpture, electronics and “hair rooting”: Hair-rooting services typically apply to doll heads for the creation of characters for TV and film.

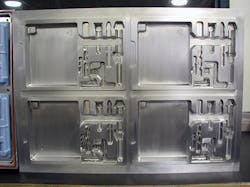

The company also offers a range of custom thermoforming services, which includes everything from 3-D design to tooling and other production-related items.

Most of its prototypes are produced in metal, foams, plastics, glass and resins, and in quantities of between one and 10.

To accomplish its wide range of “exotic” services, Cornerstone uses a selection of CNC machinery and the SurfCAM computer-aided-manufacturing program by Vero Software.

“We like the functionality and the interface of SurfCAM,” Watkins said. “We stretch the limits of the capabilities of 3-axis machines and 3-axis software.”

Cornerstone has a staff of six, including two CNC programmers who are able to program in up to four axes with a horizontal rotary table on a 3-axis mill.

The company’s inventory of machinery includes a Makino V-33 vertical machining center, a high-precision 3-axis mill; a Leadwell V-60 vertical machining center; several Milltronics VM-17 vertical machining centers, one retrofitted with a fourth axis; a CNC ProtoTRAK lathe; and a handful of ProtoTRAK mills.

“SurfCAM works well with anything,” according to Watkins, indicating satisfaction with the ability use a single CAM solution throughout the shop.

For Watkins, getting down to the business of prototyping is both an art and a science. He uses Adobe Illustrator (a vector-graphics program) and Solidworks CAD software for the design and engineering portion of his job. “We do a lot of work from photos,” Watkins said. “A lot of times, I’ll take a photo, extract the edges and bring it into Solidworks to create a solid model.” If he generates a .dxf file in Illustrator, that file can easily be imported into both Solidworks and SurfCAM.

Many of Cornerstone’s jobs are consumer products: recently, he developed a bird-feeder that could be folded flat for ease in shipping. Another job entailed the design and production of a full-scale working model of a horse’s leg, complete with anatomically correct muscles, joints, and ligaments. Watkins and his team derived all design information from a CAT scan that a by a veterinarian provided. That working model was intended to test an ankle brace that Cornerstone’s customer developed.

“The ligaments and tendons were actually cables that hooked up to gauges and indicators, so if the horse stepped down you could accurately tell how much 100 pounds of pressure, et cetera, would affected the ankle brace,” Watkins explained.

The company has designed and prototyped a display model for wines, which “looked like a giant wine bottle with shelves in the middle,” as well as a campaign for popular golf-products producer Titleist.

While SurfCAM has simplified the overall process of the company’s prototype work, Watkins cited a number of features that significantly increase efficiency in both programming and machining.

“We do a lot of thermoform tooling for the packaging industry, and all of the tooling is vented with tiny holes of different depths,” he explained.

To machine the thermoform production tool, Watkins drills a one-quarter-inch diameter hole on the backside of the tool within 0.030 in. of the surface geometry. On the front side of the tool, a tiny drill — which could not machine all the way through the material — is used to create a smaller hole for evacuation.

“The quarter-inch diameter holes end within 0.030 in. from the molds’ surface geometry,” Watkins said. “SurfCAM puts a center line in every single hole, and that center line can be used to determine depth, which makes it a lot easier when we machine the smaller evacuation holes on the flip side.

“Once the model is imported, I’m already programming and I don’t have to tell it how deep to go,” he said. “If I couldn’t do that and I had 100 holes, it would be 100 operations — but it becomes just one operation.”

Watkins also saves programming time with SurfCAM’s ability to use .STL files for verification. “From a programming point of view, you can run tools one, two and three, and then save an .STL file for each,” Watkins said. “If you cut a part and then want to make a change, you want to go back and verify that it will work without having to run a complete simulation of every operation.”

In other words, if Watkins wants to make a change only to the third operation, he can skip simulating operations one and two and go straight to the third tool that he wants to adjust. “It’s kind of like a fast forward,” Watkins said. “We have parts that can take a while to verify — though the efficiency of the toolpath helps a lot with that.”