Eight-Spindle Turning Speeds Through Complexity

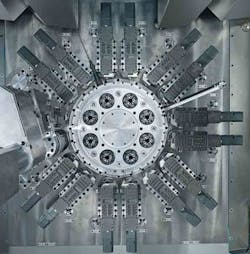

Multi-spindle machine specialist Index is preparing to demonstrate the effectiveness of its MS22C-8 modular automatic CNC turning machine for fast process capability, especially with highly complex parts. The developer indicated the Index MS22C-8 has applications ranging from automotive to medical technology, but also produces small batches efficiently and economically. As for versatility, the Index MS22C-8 can be bar-fed or loaded with chucked parts.

The MS22C-8 can be configured to operate as an 8-spindle machine, a double 4-spindle machine, dropping two complete parts at a time, or a machine with double rear-end machining. In a double four-spindle mode, the system runs as two machines working together simultaneously on one base. Every second tool station always has simultaneous access to the same tools.

Index further noted that the MS22C-8 can accomplish turning, off-center drilling and thread cutting, inclined and cross-drilling, milling, multi-edge turning, hobbing, tooth milling, deep-hole drilling or slotting. Another benefit for the user is that all standard tool holders and tool holder system interfaces can be used with a range of popular adapters (Capto, HSK, VDI, Index systems.)

Within the Index spindle drum, each of the eight spindles is assigned two cross-slides that can travel both on the X as well as on the Z-axis. Each cross-slide can be additionally equipped with a Y-axis. Up to two swiveling synchronous spindles permit simultaneous rear end machining.

“Combined with a total of up to 16 cross-slides, the eight-spindle machine is therefore a true multi-talent even for highly complex machining,” according to Index.

The speed of each of the eight liquid-cooled spindles can be controlled separately. The fluid-cooled spindle drum keeps the thermal growth in the spindle carrier to a minimum. The advantage compared to the previous air-cooling approach is the higher power density in the spindle drum and the capability of energy recovery from the heated cooling fluid.

In addition, the spindle bearing temperature can be kept at a low level, which also prolongs its service life and improves thermal stability.

The cross slides with integrated drive have a low-mass design with hydrostatic bearing support. Their low moment of inertia and resulting high dynamics facilitates outstanding acceleration in operation.

When operated as an eight-spindle machine, the drum-indexing angle from spindle to spindle is 45°: if the machine operates with two times four spindles, the drum-indexing angle is 90°. Results from double four-spindle machining; two finished parts are produced by the machine per work cycle.

All Spindles Working Simultaneously

In double rear end machining, there are six spindle positions available for front machining the workpiece and two spindle positions for rear end machining, and they all work simultaneously. With this approach, it is possible to machine the rear end of a workpiece during two drum-indexing cycles.

After front machining, for which six spindle positions are available, workpieces are picked up by two rear machining units and machined simultaneously on the rear end.

Because rear end machining is done during two drum-indexing cycles, up to six tools can be used for this simultaneously with the other spindles. And, because all cross slides are located at the same travel angle to one another, free chip flow is guaranteed in each position.

The advantage of hydrostatic sliding guide in the feed axis (Z) is their outstanding damping characteristic that prevents the transfer of the machining vibrations to the adjacent slide via the headstock. This helps to mitigate vibration and rattling while workpieces are being machined — even when the eight spindles are performing the most diverse machining processes concurrently.

For example, one spindle can be used for heavy-duty roughing while high-precision finishing takes place on another spindle without sacrificing surface quality. In addition, the hydrostatic bearing is wear-free; there is neither friction nor a stick-slip effect.

The swiveling synchronous spindles are locked into the end positions by three-part Hirth couplings. The high stiffness that this achieves also guarantees that even with bar diameters up to 24 mm, rear end machining operations with very high cutting volumes and simultaneously high machining precision can be performed.

The Hirth coupling also means it is not necessary to compensate electronically at the end position. The mechanical lock ensures optimal stiffness and increases the positioning accuracy. This allows even highly complex components to be produced that require complex cut-off side machining. The swivel movement to the rear end position occurs in less than 0.3 seconds.

The advantage of the front-opening design for the operator is the excellent accessibility during setup and tooling. Moreover, there is the free chip flow down into the chip discharge chute.

To save space, the Index engineers simply placed the control cabinet “on the machine”. (Index noted it has been integrating the control cabinet into the machine roof to its multi-spindle machines for almost 15 years, and the design concept has been very well received by machinists.)

Discharging workpieces damage-free from the work area and placed on pallets in the right position for later treatment, the MS22C-8 can include optional handling solutions: machine- integrated handling with external stacking unit that ensures both destruction-free removal of parts from the machine, including measuring operations for the workpieces if needed. Workpiece data can be fed back directly to the machine control so it can automatically correct its machining parameters.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.