United Grinding Expands Internal Grinding Capabilities

The new series of internal grinding machines from Fritz Studer AG significantly expands the range of machines available for that purpose. The Studer CT series is among the range of ID grinding machines offered by United Grinding Technologies Inc., including 8 Studer CT models; the Studer S120, S145, and S151; and the Studer S33 and favoritCNC, which feature ID and OD grinding but frequently dedicated to ID grinding.

United Grinding Technologies is the North American arm of the Körber-Schleifring Group and supplies Blohm, EWAG, Jung, M ågerle, Mikrosa, Schaudt, Studer, and Walter machines for grinding. Its product line will address the grinding needs for workpieces in all sizes, shapes, and materials. A team of grinding experts and technicians experienced with over 10,000 machine installations and a global service/support network supports its universal, external, and internal grinders.

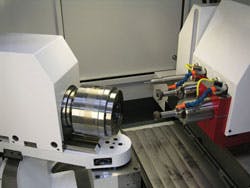

The Studer S120 has a compact footprint, cross-slide design for processing with up to two internal grinding spindles, easy automation, C-axis, a large selection of multi-application spindles, and modular configurability, making this machine ideal for applications like carbon sleeves, hydraulic valve components, fuel injector parts and other small precision components.

With a modular design, easy programming, and optional C-axis for form and thread grinding, the Studer S145 is designed to machine medium-sized workpieces up to 200 mm (7.9 in.). It is especially suited for shops that produce prototypes and small runs, or that manufacture high-precision tooling, bearings, gears, and mold components. With the appropriate configuration, the S145 also functions as an efficient production machine.

The Studer S151 grinds workpieces up to 300 mm (11.8 in.) in diameter. The capacity of the workhead and spindle turret with up to four grinding spindles, meaning it’s ready in one set-up to machine parts like turbine rotors and vanes, gears, and automotive transmission components.

Studer’s CT product line will handle small- to medium-sized internal cylindrical grinding applications, such as die plates, spring collets, tool holding fixtures, hydraulic components, and thread ring gauges in hard materials like tool steel, carbide, ceramics and glass. The modular and flexible arrangement of spindles will achieve optimal dimensioning.

And, Studer CT machines support integrated and autonomous loading systems, which adds to their flexibility and efficiency.