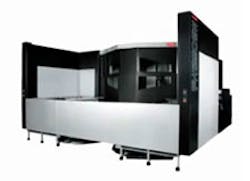

New Quill-Spindle HMC Promises "Largest Work Envelope"

The FH1250SW is an update to an earlier HMC design, with the additional capabilities of a boring mill.

Toyoda Machinery introduced a quill-spindle horizontal machining center, the FH1250SW, that combines the original FH1250SX HMC’s speed with the capabilities of a boring mill. The system was developed to increase efficiency and versatility of large-part machining through process integration.

The machine demonstrates maximum power during large-diameter drilling and boring cuts. The 60-horsepower, 3,000-rpm spindle boasts 968ft/lbs of torque, so it’s ideal for machining steel and cast metal parts. Equipped with a 5.11-in. quill diameter, the FH1250SW is capable of a 21.6 inch W-axis stroke. The spindle is engineered with proprietary bearing technology capable of accommodating a cutting thrust load up to 4,500 ft/lbs.

The machine’s standard NC table supports workpieces up to 11,000 lbs/5,000 KG table load capacity, and the Y-shaped pallet changer configuration allows for simultaneous setup of two pallets.

The FH1250SW is equipped with dual-axis ball screws in both Z and Y axis. The oil-chilled ball screws are included on the X, Y and Z axes to suppress thermal displacement during long cycle times. The 49x49 inch pallets with X, Y and Z travels allow for large applications to be handled with ease.

Toyoda sets the standard in excellence with engineering expertise and flexible systems for material handling and automation that help you innovate and increase production– with the reliability of proven technology.