With manufacturing operations using higher cutting speeds that place greater force on workholding equipment, choosing the correct system to hold a workpiece is trickier than ever. Dave Jones, precision workholding manager, Emuge Corp. and his team offer the following tips for obtaining a customized clamping solution. Following these guidelines, and staying close to your vendor, will help coping with the challenges of today’s demanding production environments.

Establish open communications. Be sure your vendor has an open ear beginning early in the quotation process. It is critical that they understand the requirements for your entire operation. Although not always immediately evident, some of this information may prove to be essential to the success of a workholding system. Supply vendors with complete operation specifications, and keep them informed of any changes to these specs even if you feel these modifications are not workholding related.

“The Emuge workholding group stays close to customers to learn about their unique challenges and production environments,” said Jones. “Doing so helps us avoid potential miscommunication and minimizes additional project costs. When we stay close to customers, we are usually kept informed without even asking. However, even when we are receiving timely updates, changes to the original specs may lead to added cost or a delay in project delivery because the design or build process may be too far along.”

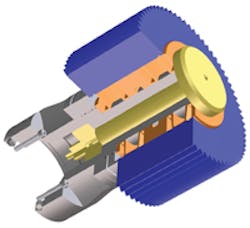

Difficult workpiece considerations. If considering having a custom workholding solution produced for you, chances are you are dealing with a difficult workpiece or operating environment. Open communications with vendors will help to ensure the best workholding solution for a specific application. For example, one challenge is holding very thin-wall parts while performing operations with high transferable torque values, such as hobbing, shaping, shaving, turning and grinding. The Emuge System SG is based on a series of short tapers that spreads the clamping forces over the largest possible area of the workpiece. The result is a rigid, accurate and repeatable workholding solution for these types of difficult workpieces.

Ensure all areas of the system are accurate. Not only should a new clamping system be precise, but several other related areas of the operation should also be reviewed to ensure the best possible results. Look at the production environment and tooling and make sure these areas are suitable for the application, such as the accuracy of the locating and clamping surfaces on the workpiece. Don’t simply rely on what has worked in the past. Also, a clean workpiece yields the best end product. When debris builds up in the clamping area of a workpiece, it may affect how the piece is being held, and negatively effect the outcome of the entire operation.

Consider the volume of work to be performed. For a high work volume, the reliability of a mechanical workholding solution can be the answer. Generally, in high-volume production a hydraulic solution is not preferred because of its maintenance requirements, due to the volume. However, in the case where a workpiece has a challenging bore-to-length ratio, or limited space constraints — both of which can be prohibitive to a mechanical solution — a hydraulic system with high accuracy and repeatability may be an alternative.

Consider future uses of a workholding solution. With an eye to choosing a clamping solution that will serve now and into the future, when a vendor is designing your fixture take the time to convey what you believe your future needs will be. Perhaps the workpiece is just one of many in a series or part family. This may mean that relatively minor changes would have to be made to the workholding device to accommodate the new workpieces.