As machine tool OEMs gear up products to accommodate shops manufacturing wind turbine components, so too are those companies producing gauging and measurement equipment to handle the large components.

According to The L.S. Starrett Co., wireless data systems can benefit wind turbine manufacturers who have or are planning to have largescale operations. Wireless data collection systems, said the company, provide reliability and flexibility by automating data collection for improving speed and accuracy when compared with manual recording.

Further, wireless systems let shops bring the gauge to the work for more application flexibility and safety because there is no costly and cumbersome wiring to deal with. In Starrett’s DataSure wireless data collection system, for example, miniature radios connect to the data output ports of electronic tools.

There are then gateways that connect to a PC via the USB or serial port. Signal routers can significantly extend the system’s range in increments of 100 ft each. Routers can be configured to create a mesh architecture. The system then gathers data from the measuring tool and sends it to system software by the shortest or most robust connection path.

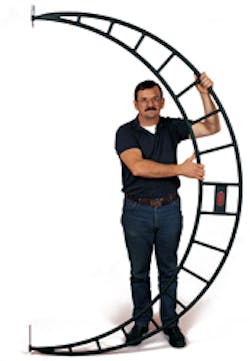

Starrett also produces custom micrometers ideal for shops machining wind turbine and blade components. These extra-large micrometers include the company’s No. 724 Big Mic that measures in a range of 72 in. to 78 in. and has interchangeable anvils.