Simultaneous 5-Axis Machining Gets Seal of Approval

Future Advanced Manufacture Ltd. is the largest user of Vero’s VISI CAD/CAM system in the U.K., and its latest successful application involves using VISI to produce complex acrylic tooling for a turbine blade sealing device, for one of the world's leading aerospace suppliers. Although the company has been using VISI Machining (three, four and five axis) for many years, the recent project required strong CAD tools and support from Vero.

Vero Software develops CAD/CAM/CAE programs that are widely used in shops that produce plastic injection molds and progressive dies.

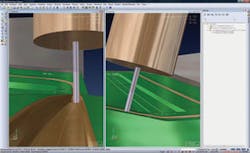

Future AM’s task was to produce a mating pair of complex aerodynamic components that seal together by means of a multi-axis dovetail groove that followed an elaborate path around the face of a turbine blade. It was clear at the quotation stage that the original CAD data was not compatible for manufacturing, and would require manipulation, as it contained both corrupt surfaces and steps that were un-machinable.

After initial consultation with the client and Vero’s 5-Axis support engineers, it was agreed that the model could be adapted better to suit the relevant machining strategies. The original solid model was provided as a native SolidWorks file and loaded directly into VISI for editing.

Mike Sullivan, Future AM’s director and project manager, explained: "The main reason for re-modeling was because the original groove geometrical form was built using a series of complex combined surfaces that included the side wall and upper and lower radii.

“Simultaneous 5-axis machining is very reliant on surface quality and continuity,” Sullivan continued; “the tool movements multiply any imperfections. Using the powerful multi-surface editing capabilities inside VISI, it was possible for me to deconstruct the geometry and re-model the blends in the complex groove to suit 5-axis dovetail machining, yet still provide an acceptable sealing solution within the customer’s original design."

Once approved, the new model was used in-house, where it was also necessary to add side-extension surfaces for machining purposes, add clamping blocks, and create capping surfaces for finishing the master insert faces.

The machining was performed on a standard Bridgeport VMC 1500 XP3 with an integrated Nikken tilting rotary table and a 1,2000-rpm head. As the finished components were machined in PTFE, the relatively high surface feeds/cutting speeds were only restricted by the continuous 5-axis tilt and rotation speed of the table. Because of the way that the groove followed the hilly terrain, finish machining was reminiscent of a rodeo ride. The machining envelope in this instance was around 400 mm3, although the company machines and inspects in excess of 2 meters.

Future AM specializes in project management, design, and manufacturing for clients in some of the world’s most demanding industries, including the aeronautical, space, medical, and oilfield exploration sectors – market sectors with a continuous need for ongoing research, development and testing. The firm has developed a particular expertise in the aerospace industry, gaining AS9100 certification towards the end of 2009 for its capabilities for producing ‘high complexity components and assemblies for aerospace applications.’

“Our clients demand excellence both in the accuracy of the design and build and also in the efficiency of the operation,” Craig Peterson, managing director, said. “We are one of Europe’s leading designers and manufacturers of aerodynamic models used in wind-tunnel tests. We have worked with Airbus and The Aircraft Research Association in Bedford (England) for a number of years producing large models with overall accuracies down in the range of 25 to 50 microns. Long-term success comes from continuous improvement in our systems and technology, and investment in highly skilled engineers. Five-axis simultaneous machining is just the latest example in that process of re-investment.”

Future AM’s world-class reputation helped it to win its first significant contract in the U.S. “We can’t say much about it,” Peterson confided, “except that making titanium blades for a new propulsion system requires accurate, trouble-free machining software together with very stringent validation processes. Whereas we had confidence in our VISI programming strategies our existing metrology tools were not able to validate the result in a format that was acceptable to the customer. So, we turned to Renishaw and installed a combination of their REVO scanning head and MODUS software, capable of comparing the finish-machined product, directly to the customer’s CatiaV5 models.”

The impressive results demonstrate Future AM’s ability to program and machine highly accurate, thin aerodynamic sections using VISI Machining. The new systems are helping the company keep ahead of its European competitors in aerodynamic testing. “You always run the risk of being left behind,” Peterson observed, “but the ability to integrate all of these technologies enables us to offer a truly comprehensive, ISO 9001:2008 or AS9100 certified service.

"Our aim is to always focus on engineering development work with specific attributes, such as high intellectual-property values, safety-critical applications, and highly complex design,” Sullivan explained. “If you set out your strategy in this way, your team must be able to deliver repeatedly good results within very tight timescales.”