CNC Programming System Cuts Micromachining Time

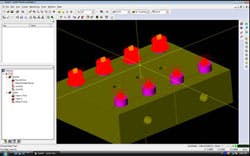

This ESPRIT screen shot shows what the programmer sees when preparing a precision machining job for EDM electrodes.

Die Technology Inc. is a Minnesota shop that performs precision machining, with a specialization in producing dies for materials less than 0.005 in. thick. The company prefers to perform operator-intensive jobs during the day and, whenever possible, run its machines unattended at night. It has made substantial additional time-savings by switching to ESPRIT® from DP Technology and using that software’s mold capabilities to create CNC programs for producing electric discharge machining (EDM) electrodes. Only about four hours were required to train each of the company’s programmers to use the software, and they have been able to program nearly every part in substantially less time than was required by the software used in the past. For example, it took just 90 minutes to program the first of a family of EDM electrodes for making molds for catheter tips, and only 10 minutes to program subsequent parts.

Tight clearances for thin materials

Die Technology Inc. was founded in 1988 as a contract machining shop with a specialty in wire EDM, focused on building progressive dies and precision stamping dies. It designs and builds precision stamping dies, tools and fixtures for customers in medical, electronic, defense, and telecommunication industries. It also provides precision wire and sinker EDM machining services for a range of OEMs. While Die Technology is still heavily involved in wire EDM, in recent years its primary focus has turned to precision machining and micromachining. At least 95 percent of the dies and tooling it produces now are for materials that are 0.005 in. thick, or less. Some of these are less than 0.001 in. thick.

Cutting clearances between the punch and die are typically no more than 10 percent of the material thickness, which means that clearance on a 0.001-inch thick material is in the range of 0.0001 inch. A high degree of accuracy is required to guide the punch into the die with such minute clearances. This means that tolerances have to be very tight on all critical components, including dies, punches, guided stripper plates, die plates, die inserts, etc. Die Technology uses 4-axis wire EDM to produce the entire die assembly. A high degree of accuracy is necessary to produce the wire EDM electrodes used by the company.

Autonomous machining

One of Die Technology’s unique capabilities is performing many machining operations without operator attention. The company uses Agie Charmilles Progress V2 machines, which have a number of features that make them suitable for autonomous operation. For example, these machines handle standard wire spools up to 25 kilograms and thread reliably in multiple parts or multiple openings in a single workpiece. They provide considerable flexibility for operators to set up multiple workpieces on the machine table.

An example of an EDM electrode that Die Technology programmed in ESPRIT. The electrode is used to make a mold to produce catheter tips.

“We are normally manned for 12 hours a day, from 5:30 am to 5:30 pm,” explained Die Technology owner Dale Skoog. “When we have a backlog of work, we focus during the day on jobs that cannot run at night. When it’s time to go home we leave the machines on and take advantage of the night hours. We have increased the average time that our machines operate from 2,500 to 3,500 hours per year. The cost of operation is much lower at night than during the day since the only variable expenses are consumable tooling, electric power and wear and tear on the machines. We also use the autonomous features during the day to enable operators to run two or three machines.”

Die Technology has used a number of different CNC programming systems. As it implemented more advanced machine tool technology and methods, these programs failed to keep pace and were replaced. The company then switched to ESPRIT CNC programming software for wire EDM and later began using ESPRIT for metal cutting and graphite. With the new software, the company’s programmers found they could create CNC programs that provide the levels of accuracy and productivity needed to profitably produce EDM electrodes to very close tolerances.

“ESPRIT does an excellent job of programming all of our machines and is frequently updated to take advantage of new machine tool capabilities such as the autonomous machining features of Agie EDM machines,” Skoog said. “ESPRIT is so easy to use that it takes only about four hours to train new programmers. In today’s economy, we need to give our people as many skills as possible to stay competitive. We train all of our people to program both wire EDM and milling operations in ESPRIT.”

Program for EDM electrodes

Wyatt Neubauer, programmer for Die Technology, provided an example of an EDM electrode that the company recently programmed in ESPRIT. The electrode is used to make a mold that produces catheter tips. Each catheter tip is shaped like a cone with a ball at its point. Neubauer began programming the EDM electrode by opening up a SolidWorks file containing the part geometry in ESPRIT. ESPRIT recognized the part geometry as a single contoured feature. Then, he defined the stock shape and used ESPRIT to automatically create toolpaths to mill out the part.

Neubauer began by selecting the Z-Plane concentric roughing milling strategy, which traverses the circumference of the part at a constant Z level and then drops to a lower level to make the next pass around. This milling strategy includes an extensive set of high-speed cutting features, such as the rounding of sharp angles and fluent step over with trochoidal feed to avoid straight paths, allowing climb milling in all situations. It automatically optimizes the program based on the results of the previous machining cycles, eliminating any “air cutting” and minimizing retract movements. He selected approach/retract positions from a wide range of options provided by the software.

Neubauer used a different milling strategy, called Planar Zone Re-Machining, to finish spherical tips on the ends of the cones. Planar zone re-machining is designed for machining particularly complex geometries using zigzag or concentric toolpaths. The clearance distance from walls is independently controlled and may be different from clearance used with respect to the stock.

Finally, Neubauer used a high-speed Z-Level finishing cycle to finish the part. This strategy generates passes of variable height in support of a constant scallop height, producing a high-quality finish on the work piece. This machining strategy is optimized by levels and zones with a smooth circular approach movement and fluent stepovers.

Simulating machining

Neubauer then simulated the entire manufacturing process in order to verify that the part produced by the program met the customer’s requirements. He viewed each individual cut in the entire machining process in dynamic 3D solids. He then inspected the virtual part by comparing the as-machined workpiece to the original part design. He zoomed in on the simulated part to determine whether or not it matched the customer’s design. The simulation provided a comparison of the toolpath with the solid model and displayed any part violations, as well as the amount of material remaining, using a customizable color format. The simulation took only a few seconds to run and enabled Neubauer to identify and fix programming problems before they reached the shop floor.

The final step was post-processing, which entailed Neubauer generating the code that runs on the machine on which the part will be manufactured. ESPRIT’s extensive post processor library contains posts for a large number of machine tools, and the software includes a post processor generator to modify existing posts or create new posts from scratch.

Die Technology also uses ESPRIT to program its EDM machines. ESPRIT provides a universal EDM contouring cycle to machine any contoured mold, die, core, cavity, shape or profile. This versatile machining cycle supports any number of straight or tapered rough and skim cuts while optimizing wire-cutting paths. Strategies for all styles of EDM machining, such as punch, die, multi-cavity parts and unattended machining are included. Between cuts, ESPRIT automatically handles all the necessary wire-cut and wire-thread instructions, and part-handling functions of the machine: flushing, tank fill and tank drain.

ESPRIT supports every make and model of Agie EDM machine for full exploitation of Agie’s unique machine capabilities, including dual tapering, upper and lower tapers, and sophisticated advanced conics. For the AgieVision, ESPRIT accepts the Ra, Tkm, and Te technology settings to create the script file format (SBR, SBL and ISO).

“Staying competitive in the precision machining business requires the right combination of technology and skills,” Skoog concluded. “ESPRIT has played a major role in our success by making it easy for our programming team to utilize advanced machine tool capabilities.”

Related Articles

[IMTS Preview] GibbsCAM to Show New Capabilities

[IMTS Preview] Makino to Showcase F5 Vertical Machine, New Technologies

Entrepreneur Planning High-Tech Machining Complex