Better Toolpaths Make Manufacturers More Globally Competitive

North American manufacturers must balance a multitude of issues to stay profitable. Increased competition from overseas manufacturing with its access to cheap labor, the reduced availability of qualified workers in the manufacturing trades, and tightening employee and environmental regulatory requirements, are just a few issues challenging the wits of manufacturing executives today. Equally important is the struggle to shift into a new era of production – from high-volume, low-mix work, to the increasing number of low-volume, high-mix short-run projects coupled with just-in-time ordering – which has placed high demands on all aspects of manufacturing.

Because of all this change and instability, the costs of manufacturers’ traditional growth strategies – such as adding floor space, capital equipment, personnel and overhead – present a more significant risk than in the past. Manufacturing executives and managers must assess all the factors relating involved in transforming resources into goods and services.

Capacity, and underutilization of resources — Central to this is assessing production capacity, because the maximum number of goods that can be produced over a given period under normal working conditions is the one barrier that every manufacturing business faces.

Capacity decisions affect production lead-time, operating costs and the company’s ability to compete. Inadequate capacity can lead to the loss of customers and business. Excess capacity can drain the company's resources and prevent investments into more productive ventures. The question of when capacity should be increased, and by how much, is the critical decision. Failure to make capacity decisions correctly can be damaging to the company’s overall performance, particularly when time delays are present in the manufacturing process.

One critical aspect of poor capacity planning in manufacturing is the failure to fully realize the capability of existing machining resources. For many machine shops, increasing capacity means adding more equipment and workers, and extending valuable floor space. But, the true production capacity of a machine tool is seldom fully realized by those responsible for assessing production volumes. This factor is so important that it can make or break the profitability of a machine shop. At the very center of this issue is the inefficiency of computer-aided manufacturing (CAM) toolpath generation, which plays a critical role in fully influencing machine production capacity.

Toolpath Deficiency, Productivity Potential

CAM software permits companies to manufacture goods faster, more efficiently, and at a lower cost, by simplifying and streamlining the toolpath generation process. But, even as CAM packages have continued to evolve over the past 40 years and expand their ability to process higher levels of throughput, they have done little to make more efficient toolpaths. Hence, a high level of inefficiency exists in conventional toolpath generation, despite the otherwise high-performance levels of modern CAM systems.

“Millions of manufacturers believe that the toolpaths native to their CAM systems are designed for optimal performance,” said Gregory M. Saisselin, vice president of Worldwide Sales for Celertitive Technologies, a developer of toolpath generation software, “but they are not. Productivity is lost because the toolpaths actually prevent the machine tools from operating at their full capability. In the vast majority of cases, they are running, at best, at 50% percent of their productivity potential.”

Conventional toolpaths force a machine tool to drive a cutting tool along a path that repeatedly varies the material removal rate, with numerous requirements to start and stop, and with sharp directional changes. Machining loads become extremely high in such instances, yet make up a relatively small percentage of the overall toolpath length.

But, since milling parameters – such as spindle speed, feed rate, cut depth and cut width – must be set conservatively enough to allow the tool to survive these moments of brief, but intense tool load, it makes these parameters quite inefficient for machining the rest of the part. This results in unnecessarily long machining times, and significantly reduced productivity potential.

Toolpaths transforming machining productivity — For many manufacturers, using more efficient toolpaths to drive their existing machining equipment has proven to be a much more cost-efficient and workable solution to managing the variables of order size and improving production throughput, compared to investing capital into new machinery and the labor requirements to support it. Groundbreaking toolpath technology has helped manufacturers reduce costs, produce more parts, and lower project bids, while utilizing their existing equipment and infrastructure.

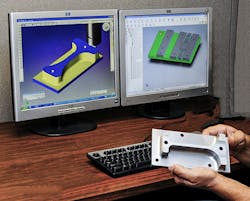

This machine-efficiency transformation is being played out in thousands of machine shops and manufacturing plants in the United States and worldwide. Spearheading this change is a science-based toolpath, called VoluMill™, developed by Celeritive Technologies Inc., for high-efficiency, rough-milling operations.

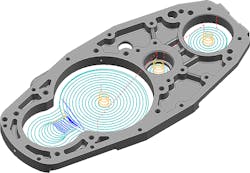

VoluMill is a science-based toolpath technology that equips machine tools and cutting tools to operate at peak performance. It performs all of the complex calculations required to determine the best cutting strategy for any part. Its toolpaths drive cutting tools along a path that maintains a consistent tool load and has no sharp corners or sharp directional changes: the resulting toolpath is smooth and flowing with no repeated stopping and starting. VoluMill keeps a constant step-over whenever possible, resulting in shorter path lengths than other approaches. This produces even machining loads with uniform chip formation, and excellent heat evacuation.

By avoiding sharp directional changes and controlling the rate of material removal, the toolpath makes it possible for tools to cut faster and deeper, while greatly reducing stress. The toolpath evens the loads on machine tools and cutting tools, significantly extending tool life.

“This toolpath solution increases the productivity for any two-axis, three-axis or two-plus-three-axis rough-milling application,” Saisselin continued. “It dramatically reduces machine cycle times, enabling the production of more parts per hour. This means increased profitability and increased asset utilization for the shop.”

Application Universality Drives Acceptance

Since its 2008 initial release, VoluMill has gained global acceptance in dozens of various manufacturing sectors, such as aerospace, automotive, medical equipment, heavy industrial, oil-and-gas, and consumer products. Many top manufacturers have embraced this new technology, thereby eliminating the costs and risks of traditional growth initiatives like adding floor space, equipment, personnel, and overhead. Manufacturers are improving machining performance from 50 to 300% without the need to make changes to existing equipment and infrastructure.

“One factor that has pushed the acceptance of this toolpath technology is its adaptability,” Saisselin explained. “It can be used on any material, any machine, and in any industry. It is also CAM-system neutral. The toolpath solution can easily blend into any machining environment, without having to change CAM systems. This is a definite advantage for machine shops that would like to significantly improve their toolpath performance without complexity.”

Well known machine tool and cutting tool manufacturers not only approve of VoluMill, they use it for their own production. It is integrated into seven of the world’s leading CAM systems, and consistently performs better than the native toolpaths.

“We use Siemens NX with the VoluMill plug-in,” offered Chuck Shannon, with General Tool Company in Cincinnati. “Tool life is dramatically increased due to the reduced load and heat on the cutter. We obtain higher metal removal rates than traditional cutter paths.”

Not all manufacturers are quick to accept this advanced toolpath technology, however. The biggest reservation is the initial disbelief that it could so significantly improve machining performance over their existing CAM systems.

“We were very skeptical of the time reduction and extended tool life,” said Jake Kopveiler, with Performance Tool and Die in Detroit Lakes, Minn. “But, after using it for a short time we were running at feeds ten times faster than before.”

The recognition that streamlining toolpath performance can significantly improve machine efficiency and production capacity has prompted a number of CAM software offerings following in the footsteps of VoluMill. None, however, have been able to keep pace with its market acceptance or its toolpath performance.

This is largely because Celeritive is focused solely on science-based toolpaths engineered for bulk material removal. All of its efforts, supported by the company’s system designers and engineers, are singularly focused on developing and improving upon the best possible toolpath software.

“The introduction and industry acceptance of VoluMill is nothing short of revolutionary,” Saisselin said. “It has completely changed the way metal is cut. It throws out everything that has been done in the past, and has introduced a better system of toolpath generation.”

Although toolpath generation is but a component within complicated CAM systems, it is a very critical one that plays a vital role in machining. The benefits of an intelligently engineered toolpath technology in use within a manufacturing facility can have extensive implications. Increased machine capacity means a greater volume of finished parts can be produced in less time, which provides for greater flexibility to meet just-in-time delivery schedules. Increased machine capacity also delivers higher profit margins for manufacturing centers. It enables more competitive bids to be placed, even for projects not considered financially viable previously.

While many companies have reduced their in-house manufacturing capability, and outsourced their manufacturing and machining operations to out-of-country locations like Mexico and China to cut manufacturing costs and remain price competitive, a growing number have opted to not only retain, but expand their skilled manufacturing and machining facilities within the United States. For American machine shops, this new toolpath technology has a critical impact on these facilities’ ability to compete more successfully in price-sensitive North American and world markets.

This represents nothing less than a game-changing opportunity for manufacturers. Those companies that embrace this technological transformation in toolpath performance cannot help but emerge as leading players in their highly competitive marketplaces.

Jim McMahon writes on automation advances in manufacturing.