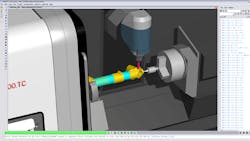

CGTech released a new version of its Vericut software for machining simulation, for use with all types of CNC systems, including machines built by Mazak, DMG/Mori Seiki, Makino, Matsuura, Chiron and Heller. The software developer specializes in numerical control (NC/CNC) simulation, verification, optimization and analysis programs, and also offers off-line programming and simulation software for automated composite, drilling, and fastening machinery

Vericut 7.2 has enhancements that accelerate simulation time, thereby reducing the time required for manufacturing engineers to develop, analyze, inspect and document the CNC programming and machining process. The new version also includes hundreds of customer-driven updates, according to the developer.

“For Vericut 7.2 we continue to focus on the customer's use of Vericut and how we can improve the simulation process effectiveness,” stated product marketing manager Bill Hasenjaeger. “We added features to the user interface to simplify the most common user actions and invested significant developer hours to increase speed by more thoroughly taking advantage of multiple processors and background processing.”

Also new in the latest release is the ability for programmers to optimize a NC program from a saved simulation. Users can adjust and re-optimize without rerunning the simulation. A new interactive panel displays cutting conditions immediately, anywhere in the machining process. The user can navigate the NC program to evaluate cutting conditions and quickly see the results of adjustments to optimization settings.

Vericut runs as a standalone program, but it can be integrated with CAM systems, too, including those available from Siemens PLM Software (NX), Dassault Systèmes (CATIA), PTC (Creo Parametric), CNC Software (MasterCAM), Vero Software (EdgeCAM), OpenMind (hyperMILL), Delcam (FeatureCAM and PowerMILL), DP Technology (Esprit), Cimatron Group (CimatronE and GibbsCAM), among others.

Version 7.2 includes more than 100 CAD/CAM interface updates, so setup continues to be fast and efficient. With an interface to Vericut, the user’s stock, fixture, and design geometry is transferred to Vericut in the correct orientation, automatically, along with the NC program, tooling, machine and control data and other simulation parameters. After the transfer, program simulation is available with a single click.