CAD/CAM and More For the Mold and Die Industry

“Cimatron says the first thing a mold shop has to do is design the mold assembly, so twothirds to three-fourths of the CimatronE product is specialized, very powerful design CAD software for people who design molds with thousands of components,” William Gibbs, president of Cimatron North America said.

“It has automated quoting for the guy that has to quote a mold.

“It draws components from custom catalogs so that all the pieces that go into your mold are being drawn from the same catalog.

“The product is capable of designing huge mold assemblies with thousands of pieces, and has bill of material and all sorts of features and functions that are very important to product lifecycle management.

“It has completely integrated and associative mold design and machining capability, and most of our Cimatron sales people spend all of their time calling on mold and die shops,” Gibbs added.

Cimatron recently merged with Gibbs and Associates, the developer of GibbsCAM, and William Gibbs became president of Cimatron North America and a member of the Cimatron board of directors in addition to remaining president of Gibbs and Associates.

“We haven’t had much technology sharing between Cimatron and GibbsCAM because there hasn’t been a need to do so. The products are both mature and complement each other,” Gibbs said.

Cimatron was established in 1982, has more than 40,000 installations worldwide and is focused primarily on the mold, tool and die industry.

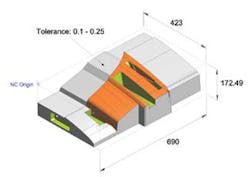

The product line is a group of modules that are centered around the CimatronE mold making product, with emphasis on the quick building, editing and re-use of tool subsystems such as runners, cooling systems and mold base configuration. The CAD tools include solid, surface and wire-frame functions that are designed to work with non-stitch models and poor quality imported data.

The package can import almost every file type in use today and converts it into a native mode format that is used throughout the Cimatron product line. It has full associativity so that changes made at any stage of the design process are automatically updated in all of the modules.

It also handles projects with thousands of surfaces, provides the automated bill of materials, automates drawing generation, uses catalogs to speed design and to control the use of standard parts, has optimized parting, flexible mold base manipulation, customized ejection systems, and has simplified cooling system and runner design.

CimatronE Die Design is fully integrated from progressive die quoting and strip design to final production and offers die makers the same features and functions of CimatronE Mold Design tailored to fit die design, including seamless hybrid surfacing and solid capabilities for forming shapes and punches, built-in finite analysis, fast blanking capability and dedicated die making tools that include nesting and trimming punch.

The software’s EDM Electrode module enables electrode design to be done in parallel with the splitting of mold core and cavity, and allows multiple users to work on the same project safely.

All of the Cimatron modules offer a fully integrated solution from quoting to delivery with full associativity across the entire product line.

The modules are designed for concurrent engineering with no data translation needed once files are imported. While the product line does have a built-in CAM function to handle 2.5- to 5-axis machining, wire EDM, mill-turn, rotary milling, multi-tasking and tombstone machining, its real strength lies in the design function.