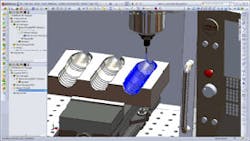

Geometric’s PLM technologies allow manufacturers to formulate and implement global engineering and manufacturing strategies that make product development more efficient. CAMWorks is a computer-aided manufacturing program designed to operate in SolidWorks.

Along with the established benefits of the program and its support for SolidWorks 2012, Geometric said the new release offers feature-recognition performance and improvements; Version 4.0 of VoluMill, with the new non-concentric milling technology that reduces cutting-tool loads and evacuates chips more efficiently; significant time reduction while saving files with large number of toolpath moves; an ability to add new tools into the TechDB from within CAMWorks; shaded display of “Contain” and “Avoid” areas; and turning roughing operations that now support user-identified inserts.

“We constantly strive to meet the requirements and changing needs of our users, while also ensuring they benefit from the latest technology advancements for machining,” explained Bruce Wiener, director of R&D for CAMWorks “Providing them with the newest version support for SolidWorks, reinstates our commitment toward always making CAMWorks ready to be paired with the latest upgrade in their design CAD package.”

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.