Two retrofitting options can increase a machine tool's productivity and its return on investment.

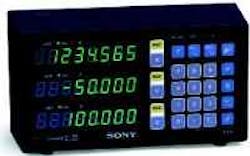

Sony's Millman is an economical choice for complete 2 and 3-axis milling applications. Centerline and bolt-hole calculations dramatically reduce setup and run times. Millman packages work in the harshest shop floor environments where liquid, solid, and airborne contaminants can compromise the performance of other scales and reader heads.

Sony's retrofitable CNC, called Millstation , simplifies programming, reduces training time, eliminates crashes, and improves productivity. Not only does this package offer brushless AC servos and drives, precision-ground ball screws, and a high-resolution LCD color display, it includes an industrial-grade PC with a Pentium 133-MHz processor and a Windows 95 operating system. Millstation also accepts standard ISO part programs from external sources such as a CAM system.

Machine tools are large capital assets meant to last a long time. It's not unusual for a company to keep a machine tool for at least 20 years or more. But faced with productivity challenges, shops with aging, manually operated metalworking equipment do want to run faster and smarter. Most have a genuine desire to optimize machining processes, increase efficiency, and improve their return-on-investment (ROI) just like every other business.

Take, for example, a company with several milling machines. If management wants to boost overall efficiency, it can either purchase all new equipment or upgrade the company's existing manual milling machines. Deciding on the latter involves retrofitting digital readouts (DROs) or computer numerical controls (CNCs). Both of these retrofitted packages are obviously less expensive than new machines, but determining which package is most beneficial can be tricky. Shops should know all the facts concerning the ROI before choosing DROs over CNCs, or vice versa.

The DRO upgrade

DRO packages significantly improve manual machining operations. Not only can these packages increase part quality, they can significantly cut setup and run times. One of them, for example, is Sony's Millman DRO package that fits most common knee-type milling machines.

It uses magnetic-scale technology to detect linear displacement with high accuracy and selectable display resolutions of 0.0002, 0.0005, or 0.001 in. A reader head detects position data, which is converted into digital signals for measurement and control. When compared to manual machinery, DROs shorten the time it takes to reach an endpoint, and most certainly, DROs reduce mistakes. This is due to the fact that the operator is not counting turns of the screw and watching a vernier scale, as with a manual machine. In addition, because the operator is working off a linear scale and looking at a display that represents table motion, he no longer has to worry about backlash on a DRO-equipped machine.

Collectively, Sony estimates that DROs can improve overall shop efficiency by 30 to 50%. And the pay-back or ROI on such systems can be measured in days. Typically, system cost is about $1,395. A machine's revenue may come to $25/hr at 8 hr/day. By raising productivity as much as 50%, the ROI formula is: $1,395 ÷ ($25/hr8 hr/day50%) 14 days.

The CNC option

With a CNC retrofit package, such as Sony's Millstation, operators and programmers no longer need to stand by, turn knobs, and push buttons. The simultaneous two and three-axis milling CNC graphically displays 25 machining cycles such as drilling, facing, pocket milling, frame milling, island milling, and O-ring milling. And, depending upon the particular CNC selection, operators can become programmers after a relatively short training course.

Figuring the ROI for a CNC retrofit, however, is somewhat more problematic. A lot depends upon the type of work being performed. For instance, contours such as lines, arcs, or angles are difficult to do on manual machines. Not only does setup time become a major issue, but the job would also require a rotary table to efficiently machine parts, even with a DRO.

But for illustrative purposes, consider the milling of contours with CNC. Operators set up parts and then cut all the lines, arcs, and angles without another setup. The ROI in this situation is tremendous because one can save well over 90% of setup time. And because operators already have the part program, they can machine multiple parts much faster. Consequently, by saving 60% on the first part, one could easily save 70 to 90% on any additional parts.

As for cost comparisons between DROs and CNCs, it is important to remember that, while a DRO costs only about $1,395, most people quickly add accessories such as power feed for the X and Y axes, which speeds up long travel moves, or a rotary table to cut arcs and angles. Accessories can add roughly $4,000 to $4,200 more to the DRO initial cost ($1,395 + $4,200 + installation, or approximately $5,600 to $6,200). If we compare this cost to that of a CNC, it is about one-half the price. However, with CNC, contoured parts, simple pockets, islands, and other such items machine much faster.

Finally, shops should also weigh the financing costs for CNC retrofits and take into consideration current, available control technology. For one CNC retrofit, a 5-year lease-to-own will cost roughly $300/month, whereas a new CNC mill would cost about twice that much. At $300/month plus depreciation, write-offs, and a 60 to 75% productivity improvement, a CNC retrofit makes a lot of sense.

Aside from cost advantages, today's CNC packages incorporate several technological advancements. Sony, for example, uses brushless AC servo systems and digital drive amplifiers. These offer better reliability because there are no brushes or potentiometers to wear out. They also develop higher torque at lower speeds and can accelerate and decelerate quicker than conventional DC servo motors. And machine rapid rates with AC servos are faster than comparable DC brush-type motors.

In addition, Sony employs PC-based hardware systems and Windows-based operating systems. In the past, CNCs used custom or proprietary hardware as their basis, resulting in problems as the equipment aged and went out of production. Processor boards, disks, displays, and other items were not off-the-shelf products. Thus, replacement parts were difficult, if not impossible, to obtain.

With the advent of the personal computer, the CNC industry has undergone a change from using proprietary to PC hardware. Suppliers such as Sony have taken advantage of this by creating true PC-based systems, running Windows 95.