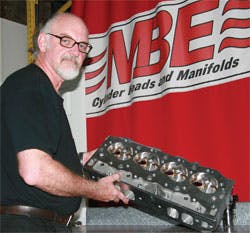

MBE Cylinder Heads and Manifolds in Mooresville, N.C., designs and builds specialty components for powerful engines used by performance race teams in NASCAR, NHRA, and others, and head programmer Mark Olson said his production plans achieve both power and precision thanks to Delcam’s PowerSHAPE and PowerMILL software packages.

“It amazes me what it can do,” Olson said. “We do a lot of manual work, then we digitize the ports, chambers and whatever else needs to be machined for the engines, and we import it into Power SHAPE.”

He said “power” makes the Delcam products effective. “PowerSHAPE has a great, powerful surfacing engine. I have yet to find something as good as Power- SHAPE to manipulate surface data.”

After perfecting the model in PowerSHAPE, Olson moves his design easily and flawlessly into PowerMILL.

“They have a very powerful automatic porting routine,” he said, and that was a big reason they bought it. “Power- MILL keeps the edge of the tool in contact with the port, as opposed to the tool’s tip. Cutting with the side of the tool provides a much better finish.”

Another aspect of PowerMILL Olson likes is the way it sees models when creating tool paths. With clearances as small as 0.015 in., he said he has never had interference or a collision using PowerMILL. He also likes the transparent interface between PowerMILL and PowerSHAPE.

“You can cut and paste common geometry from one app to another very quickly without importing and exporting.” Olson said. “You copy f rom one, paste it in the other, and I can be confident it will cut the port first time.”

“Without Delcam, it would’ve been very hard for us to handle some of the projects we’ve taken on recently,” said MBE owner Matt Bieneman.