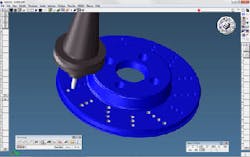

CNC software developer Gibbs and Associates is highlighting several new capabilities in its GibbsCAM program that it indicated provide “seamless integration” with the SolidWorks CAD platform, simplifying the ability to produce parts designed with that design software. This includes GibbsCAM’s ability to read and preserve features from SolidWorks files, and the ability to update machining processes automatically when a change is made to a SolidWorks file (or solid.)

The current series of GibbsCAM CNC products support 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining, and wire-EDM. The platform also provides fully integrated manufacturing modeling capabilities that include 2D, 2.5D, 3D wireframe, surface, and solid modeling.

The CAM developer said SolidWorks users will benefit from GibbsCAM’s user interface, which the developer emphasized is easy for designers and manufacturers to learn, and to use. One GibbsCAM feature of particular interest — called Feature Manager — reads and preserves features from SolidWorks files, giving the NC programmer a better understanding of the part and the intention of the designer. Programmers can use the features to identify and select areas to apply machining processes, quickly and easily, reducing programming time.

If there are changes to a part design, Gibbs notes its program is especially effective for SolidWorks users. When the updated part is transferred into GibbsCAM, it automatically updates all machining processes for that part, with a couple of clicks of the mouse, saving valuable time in the manufacturing process.

Also, SolidWorks users will appreciate GibbsCAM’s interoperability with the SolidWorks Hole Wizard capability. GibbsCAM’s Hole Manager function saves time for programmers by reading all attributes applied to holes created by the wizard and automatically generating tool lists and processes, down to the finished operations.

GibbsCAM preserves all colors applied to models created in SolidWorks, the developer notes. Since colors applied in the design process often convey information about manufacturing processes, preserving these colors improves communication between design and manufacturing, and speeds up programming time.

“We know that SolidWorks users will be thrilled with the high level of interoperability between our two products,” stated Bill Gibbs, president and founder. “Effective use of SolidWorks solids combined with our automated machining features make it a unbeatable combination for fast and accurate manufacturing.”

Gibbs and Associates will demonstrate GibbsCAM at the SolidWorks World 2012 Conference next month in San Diego, and it will highlight GibbsCAM’s new capabilities for integration with SolidWorks in a presentation there, called “Optimize Manufacturing with SolidWorks Models and GibbsCAM Automatic Feature Recognition,” at 5:30 p.m. on Sunday, February 12.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.