MachineWorks v.7 Takes Advantage of Multi-Core Processing

MachineWorks v.7 from MachineWorks Technology Ltd., the developer of solid-based simulation, verification and tool path generation solutions, reportedly includes extensive modifications to the libraries on thread safety and solid closing, so users may take advantage of multiple-core architectures in multi-core PCs and multi-core CNC controllers.

In addition, MachineWorks states that its libraries’ solid-closing algorithms will close gaps in models and fix self-intersecting loops and faces. The new solid closing module means that you can produce watertight models from almost any input geometry.

“We wanted to focus on performance and offer our customers the opportunity to gain significant increases in speed on their multi-core hardware”, states David Manley, managing director of MachineWorks. “MachineWorks solid-healing tools are another welcome addition to our technology line-up.”

Toolpath generation

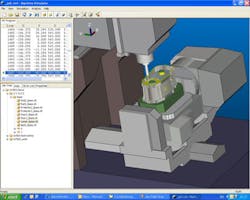

MachineWorks indicates v.7 will allow users to compute toolpaths in an environment closely coupled with simulation and verification libraries. These generators are built with “attention to geometric detail,” according to the developer, so fast generation of gouge-free toolpaths is available within the specified tolerance. Strategies include Area and rest roughing, Water line, Rasters, Radial and Spiral cuts, Constant step over, Pencil and Parallel pencil.

Tools are offered to simplify software implementation, like the MachineWorks MachineBuilder, which can turn around prototype quickly so users can quickly develop an application to sit on a CNC controller or a stand-alone PC.

Also, the developers enhanced MachineWorks Machine Simulator to help develop Full Machine Simulation, including material removal and full clash detection.