New CAD/CAM Release Optimizes Programming for Tools, Molds, More

OPEN MIND Technologies’ hyperMILL 2021.1 CAD/CAM software suite offers users new and enhanced features for efficient 3D, five-axis, and mill/turn machining. Key features include an “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation. Especially productive for optimizing tool and mold making, the editing feature is easy to use and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

To streamline access to Product Manufacturing Information (PMI) and metadata, hyperMILL offers an import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats, and attaches data to the imported faces in hyperCAD-S, making the information available to hyperMILL and its machining processes.

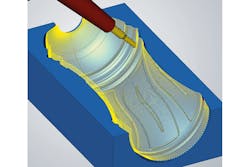

For high-quality surface finishes and to simplify programming when flank and point milling blades, hyperMILL 2021.1 offers several enhanced Multi-Blade strategies. No longer do blade surfaces need to be ruled for accurate programming results. Using the enhanced strategies, any number of surfaces are permitted for the suction and pressure sides, making it exceptionally easy to extend blade surfaces. Fillets with a variable radius are supported in the latest version. Also, for high accuracy, the enhanced Multi-Blade flank milling strategies result in smaller deviations on the suction and pressure side and offer improved tool guidance along the upper boundary in the edge area.

hyperMILL 2021.1 provides a powerful SIMULATION Center for generic NC data in turning and milling operations. Modeled after the hyperMILL VIRTUAL Machining Center, the new, modern SIMULATION Center is integrated in hyperMILL and offers an intuitive operating environment for faster simulation, independent collision checking, and extensive analysis functions. Learn more at www.openmind-tech.com

For more new products, visit newequipment.com