Expanded Functionality for CNC Simulation

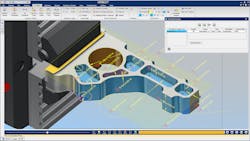

CGTECH released Version 9.1 of its VERICUT CNC machine simulation, verification, and optimization software, simulates all types of CNC machining, additive, and hybrid manufacturing processes. The software operates independently, but can also be integrated with leading CAM systems.

VERICUT 9.1 once again extends the functionality of CNC simulation with several new features that increase efficiency and equip users to do more in less time. New visibility options, plus enhancements to toolpath optimization, additive manufacturing, tooling and multi-tool stations, measuring and inspection/reporting are a few of the noteworthy features in this latest release. Hundreds of customer-driven improvements and software requests also were also incorporated.

“VERICUT 9.1 continues to enhance the user experience through continued advancements with graphics and display controls, streamlined user controls, and more new capabilities and features than ever before,” stated product manager Gene Granata. “Version 9.1 also introduces a Learn mode for Force optimization - a form of Artificial Intelligence for faster/easier NC program optimization. Using Learn mode, almost anyone can create highly optimized NC programs from existing programs, without having to reprogram them.”

Enhanced visibility — New visibility features have been added to the Project Tree and VERICUT’s right-click convenience menus for components and models, so users can toggle between visible and invisible states, or enable/disable 3-D objects for the simulation. Quick, unobstructed views of the cutting process are available along with better access to the part by removing enclosures, models of sheet metal or shrouding, and other “in-the-way” objects via “Invisible” or “Disable” actions.

New visibility options — Similarly, new features have been added to AUTO-DIFF, giving users a higher degree of control over component visibility, such as when fixture models should appear.X-Caliper annotated images — Setup Plan has been renamed to Annotated Images. VERICUT Inspection is also now included with Annotated Images. Both Setup Plan and Inspection functions are enhanced with dimensions, notes, and tolerances for checking parts at various stages of machining. Easily create professional looking and informative setup plans and inspection images stored with view layouts - ready to print as “shop aid” documents, or to appear in VERICUT’s comprehensive reports.

Shanks in cutting tool assemblies — Defining shanks as separate objects from the holder and cutter lets programmers see where these non-cutting portions of the cutter are, relative to the stock workpiece, and allows more discrete control over near-miss and collision detection properties and tolerances. Tool holder models also can be used as “Shanks”.

Streamlined optimization with A.I. — The Optimize Control window has been streamlined to fit in a single window with no tabs: Relevant features become active in subsections, depending on which Mode is selected. A new Force “Learn” mode is available, providing Artificial Intelligence (A.I.) for optimization. In Learn mode, VERICUT learns from simulating cutting, then automatically configures & optimizes tools for increased cutting efficiency and reduced machining times.

Force Charts — The new “Save All As” optimization settings option is added to the right mouse menu when clicking on a Force Chart. A new ability to ‘Learn From Results’ enables optimization settings for a tool or all tools that were analyzed.

Additive Manufacturing — VERICUT 9.1 has a new “Additive” default machining type. This means VERICUT can predict system resources that will be needed to additively build the as-designed part, including a starting stock build plate or model.

VERICUT can build multiple parts created by a “nested” build NC program, enabling additively built parts to be independently relocated or assembled for finish machining, or exported. This feature is especially helpful for Big Area Additive Manufacturing (BAAM) and Large Scale Additive Manufacturing (LSAM) parts.

DXF Import — The DXF Import feature has been enhanced with several new features. The DXF reader can now read the layers within a DXF file and automatically detect CUT/NOCUT layers. Additional layers can be checked on to use as additional components.

Learn more at www.cgtech.com