Software Offers Four New Options

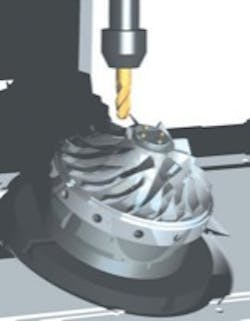

Delcam (www.delcam.com) has rationalized the wide range of functionality within its PowerMILL CAM software system into four options: Standard PowerMILL for companies with conventional machine tools; PowerMILL Pro, which provides extra strategies for high-speed machining; PowerMILL 3+2 for the programming of positional five-axis machines; and PowerMILL 5-Axis for continuous five-axis operations.

All of the options can be supplied with Delcam's new integrated data-repair program, PowerMILL Modeling, the PS-Exchange range of data translation software, and a choice of post-processors.

The PowerMILL Pro version includes extra strategies such as trochoidal machining, parametric offset machining and Delcam's Race Line machining. The company says these machining techniques minimize any sudden changes in direction within a toolpath for faster machining and a better surface finish with less wear on cutters and lower stress on machine tools.

The 3+2 option can be added to either PowerMILL or PowerMILL Pro. This includes all the milling and drilling strategies needed to maximize the productivity of five-axis machine tools.

According to Delcam, PowerMILL 5-Axis allows for fast, efficient programming of even the most demanding machining applications, such as engine ports and aerospace blades, blisks and structures. Options for both roughing and finishing include machining to or from a point, orientation through a line or curve, programming using a reference surface and swarf machining from surfaces or wireframe geometry. In addition, PowerMILL 5-Axis can generate a five-axis equivalent of any three-axis toolpath. This is often necessary when using a three-axis approach for most of a job, but where some five-axis moves are needed to avoid an obstacle or to machine as close as possible to a steep face. The software automatically tilts the cutter away from the obstacle by the specified tolerance, then returns the cutting angle to the value set for the overall toolpath once the problem area has been cleared.