New process yields strong saw blades

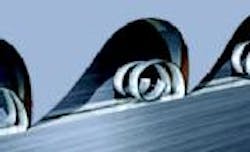

Blades employing L.S. Starrett's Bi-Metal Unique technology produce dual chips in the cutting process for a "Split-Chip Advantage."

Shops may soon be using saw blades that are stronger and faster-cutting than what's currently available, according to The L.S. Starrett Co., Athol, Mass. The company has introduced Bi-Metal Unique, which joins two strips of highspeed steel wire to a backing steel in a solid phase, using solidstate diffusion bonding. This differs from traditional weld or laser bonding, which rely on metal fusion as the union agent at the interface.

The company reports its proprietary solid-state diffusion process generates 170% more weld-contact area compared to the existing bimetal high-speed steels. The result is significantly reduced fracture and breakage at the high-speed steel/backing material interface.

Soon after initial use, the 8% cobalt teeth develop a groove, altering the blade area engaged in the cut. Starrett refers to this as "Multi-Edge Performance." As a result, the cutting stroke produces dual chips that are more-easily removed from the cut, referred to as the "Split-Chip Advantage." In coolant applications, the groove also permits increased coolant flow to the cutting surface.

"Bi-Metal Unique technology will result in better-performing saw products that we believe will be highly valued by our customers. In the coming year, our new bimetal offering will span several saw product categories," comments Douglas Starrett, president and CEO of the company.

Recent tests performed according to the BS1919 Standard compared the new blades to several competing products. Reportedly, Bi-Metal Unique delivered up to 20% faster cuts and 22% longer blade life.

Bi-Metal Unique portable bandsaw blades come in lengths from 44 7/8 to 54 in., with pitches ranging from 10 to 24 teeth/in. in both straight rake and wavy set, zero rake.