FEA software gives robotic rover an arm up

Finite-element analysis (FEA) lets engineers at Alliance Spacesystems Inc. (ASI) of Pasadena, Calif., build a lightweight, yet strong, robotic arm for NASA's "Spirit" Mars rover. By testing the arm using CosmosWorks FEA software from SolidWorks Corp., Concord, Mass., ASI optimized the design without resorting to physical prototypes.

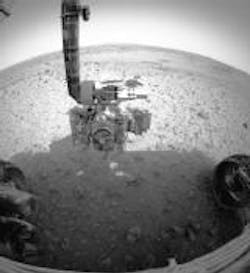

The rover's arm, which is 3-ft long and weighs 7.7 lb, has five actuators with rotating joints and an assembly at the end for holding instruments. The arm needs enough mass and strength to operate instruments and collect samples in the Martian atmosphere's high winds and extreme temperatures. However, the arm also has to be light and compact enough to meet NASA's strict weight and space requirements.

"We never could have optimized our design so precisely in such a short time without Cosmos," says ASI Chief Engineer Jim Staats.

CosmosWorks provides 3D analysis and virtual testing of parts and assemblies. It shows engineers how their designs will behave as physical objects, testing factors such as material stress and heat conduction. The FEA program is integrated with SolidWorks 3D mechanical-design software, which is ASI's primary design tool.

This photo from Mars shows the Spirit's robotic arm, which holds four geological instruments. Photo courtesy of NASA/JPL.

NASA tested the design of its Mars Exploration Rover, dubbed Spirit, using FEA software from SolidWorks. Photo courtesy of NASA/JPL.