More shops look to make marking part of the production line.

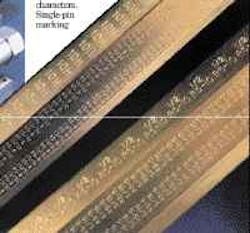

Barstock is roll marked with identification prior to manufacturing into hose fittings.

A Columbia impact marking unit goes to work marking crankshafts.

A BBC reader is necessary to read Mecco's Bumpy Bar Codes.

In many shops, parts are not finished until they are stamped or marked with permanent identification for part or lot numbers, quality control, or date and shift codes. The type of marking system a shop uses is typically based on production volume and cost-effectiveness. But lately, the trend has been to integrate part marking into production lines rather than treating it as a secondary operation.

For instance, automotive companies integrate marking into machining or assembly lines, which cuts down on labor costs, says Tom Marquart, product manager for Telesis Technologies Inc., Circleville, Ohio. "These shops obviously don't want to slow down production time to make a mark, so however long is allowed in each station to satisfy the actual manufacturing process is typically how long they will allow for marking a part," he explains.

If a shop is considering in-line marking, it should look for a system that is compact enough to fit easily into the existing machining or assembly line. It should also have a control that meshes well with the PLC controlling the line.

Marking methods

Parts can be marked a number of ways, says Frank Krembel, chief application engineer for Columbia Marking Tools, Mt. Clemens, Mich. For instance, hand stamping is a good option, he explains, when production levels are 10 pieces or less. But for applications requiring higher throughput, which is the case when part marking becomes an in-line process, shops will need to consider other marking options.

One such choice, says Krembel, is an impact marker such as Columbia's Model 78 Mite-E-Mark. These typically automatic, airpowered devices instantaneously indent a permanent mark into metal surfaces. They also have few mechanical parts and are self-contained for ease of use and reduced maintenance.

"Air-impact markers are well suited for applications requiring speed and can operate under adverse conditions even when immersed in fluids," states Krembel. These markers can be used in standalone marking operations or as part of a manufacturing cell, attached to a machining center to mark completed parts.

Roll marking, although not the most high-tech method available, is quite flexible for handling round, flat, and irregular-shaped parts. Roll markers can be integrated as a station in a transfer line, as a stand-alone machine, or part of a machining cell.

Another choice is using dot-peen markers which are electromagnetic or pneumatically operated devices with carbide pins that indent dots to form systems such as Telesis' Pinstamp model TMP4150/400 can mark up to five characters per second and, says Marquart, are ideal for on-line applications with severe spatial constraints or wet or dirty environments.

"Because the marker is so small, it's easy to integrate into a machining or conveyor line," explains Mar-quart. In addition, the TMP4150/400's sealed enclosure prevents coolant mist from getting inside the marker and fouling it up.

Lasers are another choice for production marking. These systems use low-power Nd:YAG lasers where the beam is steered and switched on and off to burn the required characters into the part. Marks can be permanent as long as part use does not abrade the marked surface. Like mechanicalmarking systems that use higher forces to control depth of mark, lasers can be adjusted to mark to greater depths by increasing power or reducing beam movement speed to burn deeper.

"Laser marking is by far the costliest of marking methods," says Krembel, "but it has tremendous capabilities when combined with computer control for marking large numbers of parts." The best applications are currently found in manufacturing cells.

In-line marking in action

One company that recently added in-line marking to its machining operations is Cummins Engine, Jamestown, N.Y. This facility, which makes the M-11 heavy-duty diesel engine for trucks, motor homes, and specialty applications, is using a partstraceability method known as Bumpy Bar Code (BBC). Engineered and supplied by Mecco Marking Systems of Ingomar, Pa., the system simultaneously imparts a 3D "bumpy" barcode, as well as an eight-digit serial number. The process takes less than 15 sec, with no delays in the production cycle.

Basically, the system pneumatically activates a chisel-shaped pin for the barcodes and a tapered pin for the numbers. The 3D marks can be imparted onto most surfaces and withstand most manufacturing processes.

With the Mecco system, indented bumpy marks are expressed by highs and lows in surface height, rather than black/white variations. The BBC reader combines laser technology with a charge coupled device (CCD) image array that reads and processes zero contrast.

There are several ways to impart a BBC mark, such as die stamping, roll marking, dot peening, laser engraving, and molding. Cummins, however, elected to use indent marking.

Production at Cummins begins with the placement of cylinder blocks on a transfer line. Blocks are individually identified by an eight-digit process number, stamped on the side of the block. The system at Cummins, Mecco's SP-202, is a dual-pin, microprocessor-controlled BBC marker that consists of a computer controller, dot-matrix marking head, and two DC linear actuators for X/Y motion.

When blocks are removed from the line for quality checks, tool change checks, temporary banks, or other reasons, machine operators record the event, the time, and the block's exact placement at the time of removal. The Mecco system simplifies the recording and archiving of this information.

An equally important advantage to Cummins using Mecco's BBC technology is quick identification of any suspect group of blocks within the overall population of blocks. With a manual, portable Mecco Marking reader, workers can quickly determine a process number while on the line, or after its removal.

The data that may be recorded for each block includes sequential process number and date and time of the block at the station. It can also include a feature code identifying why a block was removed from the line. Other information includes the part number and machine from which the part was taken. According to Cummins' Quality Engineer Tom Patton, the Mecco technology was introduced "so that any out-of-process blocks could be located before they leave the plant."

The marking technology also lets Cummins answer customer questions, even years after the engine enters service, regarding how a block was made. The marks can be read at any point, no matter how old the block is. Patton adds, "Paint doesn't hide it, heat doesn't bother it, and contaminants won't degrade it. And since it's not affected by heat treating, chemical baths, and finishing processes, it is the only marking method for components used inside the engine."

In an application similar to that of Cummins, an international automaker integrated marking into its engine/ transmission assembly line. The company needed to mark both engines and transmissions with a vehicle identification number (VIN). Since the line could not stop for the operation, the marking station had to move along the line during the marking operation, then index back to the starting point as each new assembly entered the marking station. Time and space constraints meant that both engines and transmissions had to be marked simultaneously.

For the job, Telesis' Custom Engineering Team designed a special system that used two TMM5100/400 VIN markers. They are mounted on a custom indexing carriage with pneumatic slides to advance the marking heads into position. One marker is canted at a 35° angle to access the transmission, and the engine-marking head is mounted horizontally.

A clamp assembly is also mounted on a horizontal slide. It advances toward the conveyor and closes on the engine pedestal. This coupling allows the marking system to slide along in tandem with the engine/transmission assembly until the marking process is complete.

Vertical slides raise and lower the marking heads to accommodate different engine models.

This complete multiple-slide marking system is mounted on a custom designed table. A cat track holds and protects the electronic cables and pneumatic tubing, allowing them to extend and retract repeatedly, without tangles, kinks, or wear points.

A programmable logic controller (PLC) controls the movements of the slides. A freestanding control pedestal contains all the manual controls, including auto/manual and run/bypass selector switches and a mush-room-type push-button emergency stop. It also has full array of indicator lights that track the system throughout the marking cycle.

| | | | | |

| 10 pieces | Roll marking attachment Hand holder | Hand holder Impact marker Roll marker Pin stamper | ||

| 100 pieces | Roll marking attachment Hand holder | Hand holder | Hand holder | |

| 1,000 pieces | Roll marking attachment Hand holder | Hand holder | Hand holder Impact marker Roll marker Pin stamper Laser marking | |

| Over 10,000 pieces | Roll marking attachment | Impact marker Roll marker Pin stamper Laser marking | Impact marker Roll marker Pin stamper Laser marking | Impact marker |

This selection table from Columbia Marking Tools lists the different marking methods and places them in the production levels for which they are most suited.