High-Performance Grinding Wheels

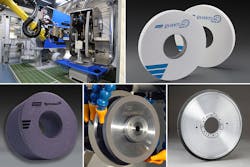

Abrasives developer and manufacturer SAINT-GOBAIN ABRASIVES will be highlighting a wide range of high-performance production grinding wheels and technology at IMTS 2022 – booth 237042 – including the new Norton Quantum® Prime grinding wheels. These wheels feature a proprietary nano-crystalline ceramic grain that contribute to productivity gains in a range of applications. The Quantum Prime grain delivers high grinding efficiency and part quality, as well as significantly longer wheel life than traditional ceramic grains.

Also demonstrated will be the new Norton IDeal-Prime internal diameter grinding wheels for precision applications, featuring the Quantum Prime nano-crystalline ceramic grain. The combination of the micro-fracture properties of the new ceramic grain from Saint-Gobain Abrasives and the retention capability of the advanced bond, ensures long wheel life, grinding efficiency, and consistent part quality with superior surface finishes, contributing to cost savings of 30% and more.

NortonParadigm® Plus “Next Generation” diamond wheels will be introduced at IMTS, with a new grain technology that complements a brittle metal bond to achieve better grinding performance on carbide round tools and periphery grinding on carbide and cermet inserts.Also debuting at IMTS 2022 will be Next Generation NORaX® N889 micro-structured abrasive belts, with a flexible design for producing consistent, fine part finishes for applications in medical, aerospace, automotive, marine, metal fabrication, and general metalworking.

Other grinding products to be presented include:

• TQ and TQX shaped ceramic abrasive grains, which offer the newest and longest-shaped ceramic grains in the industry, optimized to achieve the highest MRR and coolest cut.

• Vitron7™ cBN grinding wheels with a high-precision vitrified bond for high-performance external grinding of cam and crankshafts and internal grinding applications in automotive and bearing manufacturing.

• The Xtrimium™ range of gear-grinding products designed for demanding, tight-tolerance applications. The portfolio of gear grinding products is presented by category to provide accuracy, form holding and burn-free grinding in worm, profile, and bevel applications.

Also to be highlighted is a new Abrasive Process Solutions (APS) Program that provides custom grinding expertise by helping customers determine optimal grinding or finishing solutions for the application at hand, from simple to complex, off-hand or automated, and for metal fabrication, production grinding and virtually any abrasives operation. The APS Program draws upon the knowledge of the Norton team along with access to 30 different machines. This includes a state-of-the-art APS Robotic Automation Cell at the Higgins Grinding Technology Center in Northborough, Mass.

Get more information at www.nortonabrasives.com.