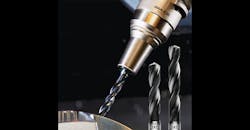

Solid-Carbide Multipurpose Drills

EMUGE-FRANKEN USA – manufacturers of high-performance taps, thread mills, end mills, drills, and other rotary tools – introduced a full line of 3XD and 5XD high-quality, solid carbide multipurpose drills for a wide range of materials and applications typically found in high-mix/low-volume job shops.

“Our extensive research and testing has resulted in a completely new high penetration rate drill design providing everyday use and maximum productivity,” state Marlon Blandon, product manager, Drills, Thread Milling.

The EMUGE MultiDRILL™ is made of a unique sub-micro-grain, carbide grade that is harder than conventional carbide grades for drilling, that still retains the ability to withstand shock and chipping. MultiDRILL features advanced TiALN-T63 coating with nano-layer technology, with surface hardness exceeding standard TiALN-based coatings for reduced friction at high temperatures.

Featuring concave cutting edges, MultiDRILL has higher chip shearing ability and a tightly controlled edge preparation process that provides consistent performance and long tool life. In addition, a double margin design helps stabilize the drill in the cut, allowing rounder, more accurate holes.

Another novel MultiDRILL feature is a drill web construction with a wide open flute form, for maximum chip evacuation.

Also, MultiDRILLs are self-centering, eliminating pre-spot drilling applications, and all tools feature coolant-thru capability.

EMUGE MultiDRILL is available in 3XD and 5XD sizes from 0.1181 to 0.7500 inch, a total of 372 SKUs in the program.

Learn more at www.emuge.com