Two-in-One Mill Solves Shop’s Productivity Challenge

Recently the machine designers at Bertsche Engineering detailed the factors surrounding its development of its new “two-in-one mill,” a design that resolved a dilemma challenging the future of a particular manufacturer. The customer had an growing order book and a limited workspace, a problem that has emerged in similar ways for manufacturers and machine shops in automotive, off-road, energy, and several other market sectors over the past five years.

“Our aerospace customer was faced with the choice of either building a new facility to house two new milling machines,” recalled a source at Bertsche, Buffalo Grove, Ill., designer of custom machine tools, automatic tool changers, and robotics, “or splitting their production between two manufacturing sites.”

Bertsche’s machine designers adapted one of their proven machine concepts in a way that offered the high productivity rates achievable with two machines, and the minimized footprint of a single unit. The investment cost savings to the customer (i.e., the costs for building a second site and relocating all production to a larger facility), as well as the additional throughput accomplished with the new machine, delivered value beyond the scope of the initial challenge.

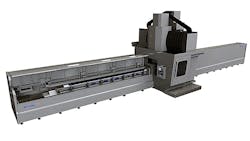

The Bertsche Dual P5 Mill has all the operating benefits of two machines: independent but linked CNCs; two five-axis machining modules (A- and B-sides), each with separate machining chambers; and the ability to machine two different parts at the same time. Still, the overall machine is nearly the same size as a single, five-axis P5 mill previously supplied by Bertsche.

The P5MILL™ is one of seven product series in the Bertsche portfolio, a fully automated five-axis profile-beam machining center with an integral “Smart Fixturing™" system.

Based on the aerospace shop’s daily production requirements, the new machine is available for operating on the A-side only, B-side only, or A and B side together. Twin integral vacuum fixture tables are designed to accept various different vacuum workholding fixtures that can be changed quickly, “at a moment’s notice,” according to the designer, with a high degree of repeatability.

To assist the operator loading the parts, each table has retractable datum surfaces that swing into place to edge-locate parts, and then swing back down when machining.

Thick-walled composite structures (up to 0.625 in.) are milled, scalloped, edge-trimmed, and drilled on all sides. High accuracy hole patterns and datum holes are drilled for determinate assembly, and then probed for accuracy. Parts are machined complete in a single setup and manufactured one-off to meet user ship-set kitting requirements.

Because aerospace machining increasingly calls for cutting composites wet, flood-coolant cutting was incorporated to the design, and composite debris is flushed into a full bed length flume system. Flood coolant is constantly circulated throughout the machine for greater machine thermal stability. High-volume mist collection hoods, integral to the machining compartment, collect and vent mist.

A special sealing system on the linear ways protects precision surfaces from very aggressive coolant fluids that must be used with composite materials. Multiple temperature sensors on the bed and X-axis slide with accuracy, to capture data for dynamic thermal compensation. To reduce the amount of filtration media, coolant is continuously filtered using a cyclonic filtration system.

In addition to the floor-space savings, with twice the productivity of the core machine designed as a single unit, the installation lowers the standard operating costs due to its greater efficiencies, and offers flexibility to the operators that matches changing daily production demands.

As for shop management considerations, the Bertsche Dual P5 Mill makes the work space easier to manage work, reduces labor costs by combining the functions of two mills, and extends tool life due to its wet-cutting capabilities for composite materials. The latter point also improves air-quality in the shop by reducing airborne dust.

As a cutting operation, the Dual P5 Mill offers a high-response rate with its two-axis head and spindle. Cutting is done with an efficiency that limits thermal growth control, and includes thermal-growth compensation.

More product quality control is offered by in-machine probing, calibration, and position verification functions, and part drying is provided as a part of the post-machining functions.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.