BY LARRY HAFTL

ASSOCIATE EDITOR

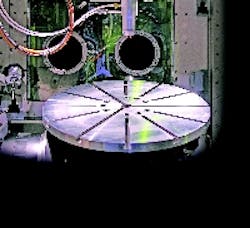

The software-controlled laser forms a melt pool on the surface of a mold as streams of powdered metal are directed into the pool to melt and build up the area.

WHEN THE DESIGN OF A MOLDED, forged, die cast or stamped part changes, the mold or die that was used to make that part also needs to change. Until recently the difficulty and expense involved in making significant changes to a mold or die often made it more cost-effective to machine a new one rather than modify the old one. But by using a process that incorporates a laser and powdered metal it has become possible to change that equation.

The process, alternately called laser powder fusion, laser powder deposition, direct metal deposition or powdered metal deposition, uses a high energy laser to create a small melt pool on the surface of a substrate — the surface of a mold or die, for example — while a focused stream of finely ground metal particles is directed into the melt pool to increase the material volume. The metal particles melt and bond with the base metal to form a built-up layer. By adding layer upon layer, the mold or die can be filled in or built up to a new nearnet-shape that can be machined to final shape and tolerance.

A wide variety of powdered materials can be used in this process, including titanium, stainless steel, tool steel, carbide, Iconel and other exotic alloys. Because the materials cool quickly and solidify with fine-grained microstructures, they have greater strength than wrought materials and no loss of ductility. Deposited material can match the base metal or make a gradual or abrupt transition to a different material and forms a true metallurgical bond. The amount and type of powder applied can be continually adjusted by software controlling the nozzle feed systems.

Since heat generated by the laser is extremely localized, mold distortion is not a problem.

This process makes retooling of molds and dies more costeffective, and offers mold designers new opportunities.

The additive nature of the process makes it easy to add mold features that have never been possible before. For example, cooling channels traditionally have been drilled into a tool after fabrication and were limited to straight-line paths. By using this process, complex cooling channels can be added to the mold that conform to the shape of the part, accelerate cooling and cut production cycle times.

Thermally conductive material can be added to the mold more effectively than ever before. If a copper core is built into a steel mold, an abrupt transition between the two materials would be subject to a great deal of stress as the mold thermally cycles during the molding process because the coefficients of thermal expansion of the two materials is so different. By using this process a gradual transition from one material to the other could be made that greatly reduces the possibility of part failure at the material interface.

The process also can be used to apply coatings and surface modifications that are free from the inherent porosity of conventional coating and plating techniques, and are not limited in coating thickness or material composition. Research on this process began in the 1980s. General Electric patented a version in the late 1980s that has been used by Huffman Corporation in Clover, SC, (www.huffmancorp.com) to create systems for fabricating and repairing gas turbine engine components. Huffman systems are used by General Electric, Pratt & Whitney, Rolls-Royce North America, Honey-well International and other component manufacturers and repair facilities. Huffman also has developed systems for applications such as medical implants and tool inserts.

Supported by government funding, several academic institutions and research laboratories have been working to further develop this process since the 1990s. Through technology transfer programs at least two companies have been able to develop commercial systems based on that research.

Optomec (www.optomec.com) in Albuquerque, N.M., built on research done at Sandia National Laboratories to create its Laser Engineered Net Shaping (LENS) system. The first commercial version of the LENS system was delivered in 1998. For the last two years, the U.S. Army has used an Optomec system at its Anniston Army Depot in Anniston, Ala., to repair components in the gas turbine engines of Abrams M1 tanks. Optomec focuses primarily on the aerospace industry but also has supplied systems for other applications.

The second company, POM Group, Inc., in Auburn Hills, Mich., (www.pomgroup.com) has commercialized a version of the technology developed at the University of Michigan called Direct Metal Deposition. POM focuses primarily on the tooling industry. Their Process Development Group provides customers with advanced tooling, tooling reconstruction, and tooling reconfiguration, while their Machine Design and Fabrication Group designs, fabricates and installs Direct Metal Deposition systems specific to customers' applications and industry needs.

One example of the work POM has done involved a mold used to make bumpers for the GMC Envoy. General Motors Corp. wanted to add halogen lights to the bumper in later models. POM was able to use its Direct Metal Deposition process to deposit new material on an old bumper mold, then machine it to the new shape, saving GM the cost of creating an entirely new mold.

Another company, Fraunhofer USA in Plymouth, Mich.,(www.ccl.fraunhofer.org) also is working in partnership with Michigan State University on new product, process and application development including design and integration of production and pilot systems at customer facilities. Fraunhofer is primarily a process research and development lab but also does production work. So far, they have delivered systems for hard facing but not for mold repair.

While these companies use variations of the same basic process, each company has developed, and continues to develop, proprietary components and techniques. At the heart of each system is a laser.

"There are four different kinds of lasers being used," said Richard Grylls, Optomec's LENS Product Manager. "CO2 and nd:YAG (neodynium-doped yttrium aluminum garnet) are older technologies. Direct diode and fiber lasers are newer. The direct diode lasers require extensive engineering to integrate them into the LENS system while fiber lasers have zero maintenance, are easy to use, do not require consumables like the CO2 lasers do and are at the least twice as energy-efficient as the older lasers.

"We use fiber lasers from IPG [IPG Photonics in Oxford, Mass., (www.ipgphotonics.com)]. We are getting more than 25 percent efficiency, which is very high for laser. They also have good coupling with the material and they have extraordinary beam quality. That makes it easy for us to integrate our optics and other components with their laser."

Huffman has used both CO2 and nd:YAG lasers and will be using IPG fiber lasers in its newest systems. Fraunhofer also uses an IPG laser in its newest system, while POM uses CO2 lasers from German laser manufacturer TRUMPF Group (www.trumpf.com).

While lasers used for welding are in the 100 W to 400 W range, lasers currently used for powder fusion are in the 1kW to 5 kW range — 10 to 12 times more powerful — and are usually the single most expensive component of a system.

Another important component of a laser powder fusion system is the software that controls the laser's toolpath. The toolpath usually is determined by slicing a CAD design into layers and then programming the laser to build up material layer by layer. However, some applications require more sophisticated software.

"The turbine blades we repair are no longer anywhere near the shape of their original CAD file," said Roger Hayes, president of Huffman Corporation. "So we reverse engineer every blade. Our vision system scans the blade, compares it to the original CAD shape, and then develops a unique toolpath for the laser based on the net difference in that specific blade. It only takes about a second for the software to calculate the toolpath and then we can begin to weld. It took us a long time to develop the vision and reverse engineering system, but it was necessary because of the very complex shapes we are always dealing with."

Companies interested in using this emerging technology have three options: hire one of those four companies to do the work on a service bureau basis; buy a system from one of those companies and do the work in-house; or develop their own proprietary system. Developing a proprietary system is not for the faint of heart.

"Knowing exactly how to do this process is more important that just having a machine," said Hayes. "We could give a machine to someone and they could spend the next 10 years working with it and still not get it right."

When a system is adjusted properly it can produce quality work 24/7, but getting it adjusted can take some time. The Anniston Army Depot took delivery of its second Optomec system in January, and even though it has more than two years of heavy production experience with the first machine it was still working on getting that second machine adjusted four months later. That is not an unusual experience because of the complexity involved in getting a specific process to run perfectly.

When a customer buys a system, they are not just buying a machine and software. Each company works with its customers to develop the process needed to produce the customer's parts. Often the company will install the system at the customer's site and work with it to perfect the process so that when the customer signs off on the system all they have to do is push the button and start producing finished parts.

These dedicated laser powder fusion systems currently sell for $400,000 to $1,400,000, but a recent product release by IPG Photonics may help bring the cost of those systems down.

IPG has released a beam splitter for its fiber lasers. This device allows several laser-driven systems to be run simultaneously from the same laser. It is now possible to run laser cutters, laser welders and laser powder fusion systems all at the same time from just one fiber laser by running fiber optic cables from the laser to the various machines. This would allow the high cost of the laser to be spread over several machines instead of requiring a dedicated laser for each machine.

This technology is far from mature, but it is developing into a unique tool that can enable moldmakers, mold repairers and others to cost-effectively solve machining problems that have, until now, been too expensive or simply impossible to solve before.