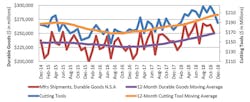

U.S. manufacturers consumed $189.1 million worth of cutting tools during December 2018, 9.7% less than during November but 8.1% more than during December 2017. Cutting-tool consumption (i.e., purchases) function as an indicator of manufacturing activity, as cutting tools are the "primary consumable" in manufacturing activities, according to the monthly Cutting Tool Market Report.

“At the end of a strong year, new orders for cutting tools slowed in the last two months of 2018, although remaining 8% above year ago levels in December,” according to Mark Killion, CFA, drector of US Industry at Oxford Economics. "Rising trade tensions and associated market turmoil, perhaps also the looming shutdown of federal government, likely gave key buyers reason to be more cautious, such as those in metals, transportation equipment and industrial machinery.”

The CTMR is compiled by the U.S. Cutting Tool Institute (USCTI) and AMT - the Assn. for Manufacturing Technology, from actual cutting-tool consumption data reported by participating companies that represent the majority of the U.S. market for cutting tools.

The December consumption total represents the second-consecutive monthly decline in the CTMR total, and parallels declining new orders for machine tools, as reported in AMT’s monthly U.S. Machine Tool Orders Report. However, the latter report is an indicator of future manufacturing demand, not current activity.

Notwithstanding the monthly trend, the cutting-tool consumption total for 2018 was $2.47 billion, a rise of 12.5% compared with January-December 2017.

“December sales trended down 9.7% from a very good November and I believe that can be attributed to the holiday season and reduced number of working days," commented Phil Kurtz, president of USCTI. "It was, however, the strongest December in the past three years and helped 2018 finish 12% higher than 2017.”