Metrology System Offers Maximum Measurement Access

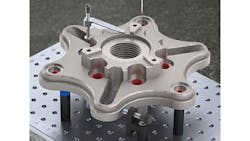

Hexagon Metrology introduced its Swift-fix fixturing and workholding system for metrology and manufacturing operations to the U.S. market. The flexible, modular system is designed to hold parts in an optimal position for inspection without distortion to the workpiece, and it’s conceived to work with various measuring equipment — including portable articulating arms, CMMs, laser scanners, and optical and multisensor vision machines.

The Swift-fix modular systems allow fixtures of varying sizes and complexity to be constructed, then taken apart and reused for other projects. The foundation of the system is the “stand off,” which screws into the base plate and is available in several diameters and lengths. Kinematic base plates come with a connection kit to join multiple base plates together for holding larger parts.

A range of accessories is available to suit all types of component holding. These also connect to each other, so exact heights can be reached. To impart more stability, Swift-fix threads are thicker than the industry standard.

Swift-fix kits include stand offs, nylon cones, spring clamps, tension clamps, toggle clamps and universal joints. Components are sold separately, in three different kits to match the needs of the project at hand.

“An effective part-holding strategy is a crucial aspect of any dimensional inspection process,” according to Hexagon Metrology product manager Eric Bennett. “Part holding is made even more challenging due to the complexity of many of today’s manufactured components; striking a balance between securely holding the part without deforming it or excluding probe access to measurement features are the critical requirements.”

He called Swift-fix “the ideal system” for managing these various needs, noting it provides the flexibility of a modular system and the “robustness” of dedicated fixturing.