Design and control capabilities

Rollomatic's VirtualGrind can be used to add features to end mills and drills not on standard catalog items.

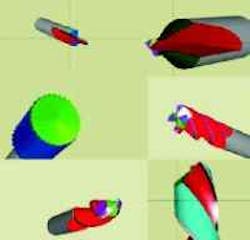

VirtualGrind software can be used to design a variety of tools as well as control the machine. To assist users in designing and programming rotary-cutting tools, as well as standard and specialty tools, the software includes visual text and graphic-description aid for operator input. VirtualGrind adds features to standard end mills and drills — like corner radius, corner chamfer, special gashes, step drills and form tools, Sspiral gash for large corner radius, Super S-gash ballnose, and more. In addition, the software handles G-codegenerated programs directly in text files, in the ISOEasy dragand-drop systems, or in a combination of standard programs and G-code simulations.

Other programs within the suite include TaperCalc, a 2D simulator for tapered tools, including flute and outside diameter relief; BurCalc, for industrial, aluminum-cut, surgical, and dental burrs; and FluteCalc, a 2D simulator for end mills, drills, high-performance drills, routers, straight-fluted tools, and step tools up to four steps.

Rollomatic Inc.

Mundelein, Ill.

rollomaticusa.com

Speed punch-press and laser-machine programming

ProFab V3.7 includes direct interfaces to SolidWorks 2004, Solid Edge 14, and Cadkey V21.5.

ProFab V3.7 sheetmetal CAM software now includes direct interfaces to SolidWorks 2004, Solid Edge 14, Cadkey V21.5, AutoCAD, and Mechanical Desktop.

Working directly with the CAD systems, ProFab eliminates the need to export and import data. During software installation, an icon is added into the CAD system. The user simply picks the icon, and the data automatically transfers into ProFab. Once there, the user has access to a comprehensive set of tools for programming a CNC turret machine. From automatically selecting the tools to nesting different parts on a single sheet, the software does the work, while keeping the user in command of the machine operation.

While ProFab V3.7 includes a long list of internal changes to increase the user's speed and productivity, the most noticeable is the tool library. "We've moved the tool library from our database into the industry-standard Access database. This lets users access the tool library from other external programs and generate reports in their own format," states Joe Bucalo, president of Applied Production Inc.

Other features of V3.7 include more standard tool shapes and a tool wizard that makes it easy to add or edit tools. ProFab is also capable of programming the Wilson Wheel for cutting and forming.

Applied Production Inc.

Milford, Ohio

appliedproduction.com

Software delivers productivity enhancements

Combining new techniques with an array of new and older equipment, Cavalier Tool & Manufacturing, Windsor, Ontario, makes molds for a variety of consumer products and automotive applications. And to maximize productivity, Ed Mueller, Cavalier's CNC programmer, tailors machining strategies to individual machines.

"The older, larger machines are more rigid, making it possible to take a larger depth-of-cut, but at a slower feedrate," says Mueller. "On the other hand, newer, compact machines require shallower cuts, but faster feedrates are possible."

Because some of the toolpaths for Cavalier's larger molds take 24 hr to machine, the company employs a number of machining strategies to protect the workpiece and cutting tool when running a lights-out operation. That's why Mueller selected Delcam's PowerMill CAM system to produce all the cutting paths. "On the higher-speed machines, it offers great control over links and leads, permits blending cuts, and generates gouge-free corner machining," he explains. "We climb mill instead of milling back and forth," he adds. "It takes a little longer because the mill must rapid back, but there is less chance of gouging than in conventional milling, where the tool pulls into the steel. And since it's important to have even cutting forces on the tool, Cavalier uses PowerMill's constant-Z-profiling strategy rather than raster methods."

In addition to the shop's other equipment, Cavalier employs a CNC ONA Sinker EDM, says Programmer Steve Glendinning. "This gives us the capability to do three burns in one setup, and we can set the machine to burn for an entire weekend. In fact, that's how we make electrodes." He explains that operators set up four to five electrodes on the machine, change the electrodes, key in the correct programs, and hit the go button.

Delcam's PS-Electrode program creates the electronic files from which the electrodes are made. An IGES file is brought from Cavalier's CAD department into the software. The electrode is then automatically generated through the software's Electronic Wizard.

"When you extract the electrode, PS-Electrode immediately generates the drawings and location sheets," states Glendinning. "I've created my own custom setup sheets with four views — front, top, regular thirdangle projection, plus an isometric view. Before PS-Electrode, I would generate each individual electrode, make an individual location drawing for it, make a separate setup sheet, and print it out," he adds.

According to Glendinning, PSElectrode easily moves in and out of the electrode Wizard as the job demands. This is helpful if it's not a fully enclosed electrode, where it burns on all sides, or if the holder needs to be offset because it's too close to a wall. Using Delcam's PowerShape, the users pick surfaces, combine them, extend them, or do whatever needs to be done. Then, they generate location setup sheets by going back into Wizard.

Delcam Inc.

Windsor, Ont.

delcam.com