STAR CUTTER CO. and HEXAGON MANUFACTURING INTELLIGENCE have established a partnership by which Star Cutter NXT five‐axis grinders will be offered with a seat of pre‐loaded ESPRIT CAM software. This combination aims to help manufacturers of complex medical tooling – like hip rasps, rotary files, bone files and drills, etc. Having certified ESPRIT post processors on the NXT ensures faster launch and reliably error‐free program code.

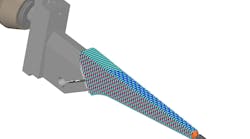

The NXT grinder is a versatile, five‐axis CNC machine with a small footprint, large grind zone and a modular design that quickly adapts to demanding application requirements. ESPRIT uses a digital twin of the manufacturing envelope to simplify the programming process and deliver edit‐free G‐ code. Customers that already have ESPRIT can add the Star Cutter NXT’s digital machine package to their existing license and program the NXT using the software they already own.

Star Cutter will feature an NXT running ESPRIT software for demonstration at its Elk Rapids, Mich. facility. Video and remote demonstrations also are available.

“ESPRIT’s proven ability in easing the programming and production of intricate parts makes it a perfect partner for optimizing the performance of our NXT grinding machines,” stated Star Cutter chairman and Brad Lawton CEO. “We are confident this arrangement will help our customers, while also providing new business opportunity for both companies.”

Learn more at www.starcutter.com