Machines roll instead of slide

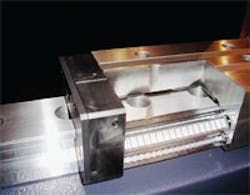

When machine tools encounter high-static or dynamic loads, linear motion roller guides offer numerous advantages for highperformance machine tools as compared with conventional plain guides, many machine tool builders say.

Linear motion roller guides deliver extremely low, consistent friction factors that allow tighter control of positioning, small incremental moves and repeatability.

There are small differences in static (start up) and dynamic friction, making motion control reliable and energy efficient. In addition, low-friction linear roller guides allow increased velocity leading to improved machining efficiency.

The rolling motion of linear roller guides, as opposed to sliding, creates little wear on raceways and rolling elements over long periods of operation. And, long life can be designed-in from the ground up as the life calculation formulas of roller guides are well established.

Lastly, roller guides require a minimum of lubrication, offering two distinct advantages. A thin film of lubrication helps to preserve accurate linearity, while conventional slides sometimes are affected by variations in oil film thickness. And, lubrication is easy. It requires only grease lubrication in most applications, saving on maintenance tasks and reducing the need to dispose of hazardous lubrication materials.

These benefits are the reason that Mazak Corp. (www.mazakusa.com) has adopted the use of linear motion roller guides in many of its newer machine models.

For example, the VCN 700D-II vertical machining center, the HCN8800-II horizontal machining center and the Integrex i-150 multitasking center with integrated material handling all use linear roller guides. The company also uses linear roller guides on several of its existing machine models.

On the operator side of its machine tools, Mazak equips its machines with its latest Intelligent Machine Functions designed to simultaneously help experienced machine operators maximize their skills and monitor themselves to realize optimum production and avoid errors.

Mazak recently introduced three new Intelligent Functions that include Intelligent Performance Spindle (IPS), Intelligent Maintenance Support (IMS) and Intelligent Balance Analyzer (IBA).

IPS monitors a variety of parameters with sensors housed in the spindle. Temperature, vibration and displacement parameters feed back to the operator, who, with this data, can prevent potential machine problems in the spindle. The result is less machine downtime and loss of production.

IMS monitors the status of perishable items such as filters, cover wipers and the operation history of several machine units. Shops can use this information to determine a preventive maintenance program to avoid unexpected machine downtime. Additionally, when the replacement time is reached for an item such as a filter, a pop-up window notifies the operator to ensure the required maintenance is performed.

IBA analyzes the balance of the machine table load and displays the amount of weight and in which locations are required to eliminate the unbalanced condition. The same system will automatically stop table rotation if excessive vibration is detected. Fixtures and/or workpieces unbalanced on a machine table can create unsafe conditions and diminish turning accuracy.