Machine Builder Goes Full Speed

High-speed machining is nothing new to Ingersoll Machine Tools Inc.

The company supplies machine tools with spindles that turn as fast as 24,000 rpm and feed at 1,200 ipm. In addition, its Manufacturing and Engineering Services Division in Rockford, Ill, uses high-speed machining when manufacturing molds, dies, and aerospace components for customers.

“Every project has its challenges, including time constraints. We realized that to remain competitive, it was essential to migrate from conventional machining to true high-speed machining and incorporate a software package that would facilitate it,” explained Bob Ponikvar, project manager at Ingersoll (www.ingersoll.com).

The company selected Strategist from Vero International Software Ltd. (www.vero-software.com). It allows the company to use all of its highspeed machines through the software’s dedicated HSM toolpath techniques and generate accurate and highly polished surfaces straight from its machine tools.

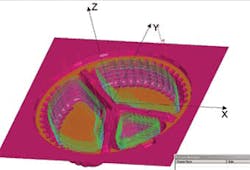

In one application, Ingersoll produced a series of vacuum-form molds machined in aluminum. The molds were used for generating clear plastic food containers, and the mold itself involved as many as 16 cavities to produce 16 parts at any one time.

Ponikvar said the molds required a lot of machining with very small detailed surfaces and that the software, along with the company’s high-speed machines, not only produced surface finishes that required little polishing but also reduced part-machining time and overall cycle time.

In addition to machining advantages, Strategist proved extremely helpful in Ingersoll’s quoting process.

During the bidding phase, Ingersoll must determine machine time to complete a project, and such calculations are essential. Customers provide 3D models, and using Strategist, Ingersoll creates enough tool paths within one hour to quickly determine how many hours and at what feedrates it will take to machine the entire part.

Strategist can run on computers that are also being used for other work, so shops such as Ingersoll can work on other projects while the software is running.