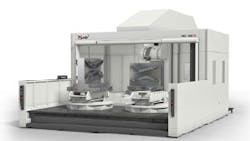

High-torque cutting of hard aerospace alloys was the determining factor that recently led Boeing to place an order for four, MAG large-part HMC 1600s, to modernize the track-and-beam line at its Portland, Ore., operation for complex machining. Equipped with MAG's T-Rex high-torque spindle, the HMC 1600 performed well in a cutting test highlighting its 2,600 Nm (1,918 lb-ft) torque and 42.3 kN (9,500 lb) cutting thrust. Combined with the machine’s ductile iron chassis construction, the T-Rex-equipped HMC 1600 provides the stiffness and vibration damping needed for chatter-free cutting of titanium 5553, Inconel, and Carpenter 465 — all commonly used by Boeing.

Phase one for modernizing the track-and-beam line will start with two MAG 4-axis and two 5-axis machines, with installation starting in August. The new machines will replace existing systems and Boeing expects they will allow it to produce more parts with higher accuracy, in greater variety and in less time and at lower cost, helping it to meet the production demands of its Next-Generation 737 aircraft program.

"Boeing's Portland machining operation sets the benchmark for hard-metal removal rates in the aerospace industry, so the bar is set high when they are considering new equipment to upgrade capabilities," stated Chip Storie, MAG executive vice president, Aerospace. "Our T-Rex-equipped HMC 1600 put on an impressive demonstration for Boeing that highlighted its stiffness, power, agility and accuracy while cutting Carpenter 465 stainless steel hardened to 50-52 Rc. With tooling similar to Boeing's, the T-Rex spindle delivered triple the metal removal rates over Boeing's current machining technology, proving it can take this elite facility to a new level of performance and efficiency."

MAG's modular HMC Series is engineered for high-precision, high-productivity machining of large hard-metal components for aerospace, power generation, pump, valve, and off-road equipment. Designed for extreme application flexibility, the machine offers maximum 3,000 mm (118 in) work-zone swing, and 14,000 kg (30,800 lb) pallet load capacity.

Major machine components, like the X-bed, Z-bed and column are ductile iron castings, while the 1,600×2,000-mm pallets, headstock, and rotary table housings are cast in gray iron. The 360,000-position full-contouring rotary table provides a rigid work platform, and a worm gear drive with clamp securely holds axis position. The machine’s rotary table positioning accuracy is 10 arc seconds, repeatable to 5 arc seconds. Positioning accuracy of the tilt-spindle is 4 arc seconds, repeatable to 2 arc seconds.

Eight spindle options include: 6,000- and 8,000-rpm/46-kW (61.6 hp) tilt-spindles with +90°/-120° degree A-axis travel; a 10,000-rpm/46-kW (62 hp) spindle; high-speed 24,000-rpm spindle; T-Rex high-torque 2,600-Nm/80-kW (1918 ft lb) spindle, and two live spindles (110 or 130 mm diameter). The high-torque T-Rex spindle is specially engineered for hard-metal cutting, while the live spindles extend W-axis reach by up to 800 mm (31.5 in), for high-precision, deep-cavity milling with shorter, more rigid tools.

MAG's Z-axis thermal compensation system is standard on the live spindle, for dynamic offsetting of spindle growth to maintain correct axial position, regardless of spindle temperature.

For tighter part tolerances and greater machining accuracies, the HMC Series is supplied with standard linear scale feedback in X, Y and Z axes, providing 8-micron (0.0003-in.) positioning accuracy and 5-micron (0.0002- in.) repeatability. Heavy-duty hardened and ground roller guide ways promote rapid traversing of up to 40 m/min (1,575 ipm) with high acc/dec rates, “double the load capacity, and nearly 10 times the wear life of ball-type ways,” according to MAG. The full work zone enclosure is pre-engineered for a clean machining environment and includes a doorway for operator access with walkway/platform inside.

The HMC 1600 is available with optional MQC (Minimum Quantity Cryogenics) and MQL (Minimum Quantity Lubrication).

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.