A foot in the door

New series of machines is the small shop’s key to entering into aerospace work.

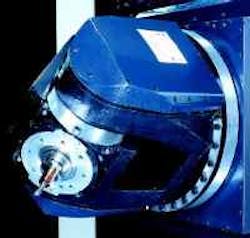

The C axis of a MAG machine's A/C spindle head rotates infinitely without having to reverse rotation to unwind cables.

Because of the MAG machine's horizontal configuration, there's no need to stop machining to clear chips. They fall freely away from the workpiece and into a chip conveyor.

MAG machines feature indexers that rotate to load a waiting workpiece while simultaneously unloading a finished one.

Adding a horizontal load station to a MAG machine lets operators easily load/unload large workpieces.

With a Module MMC automated workhandling station, MAG-machine end users set up jobs once and run them at any time—even between other jobs.

Walk the shop floor of any major aerospace company or one of its Tier-1 suppliers and, chances are, there is at least one multiple-spindle, vertical gantry-style machine. These are what it takes to cut the large monolithic parts for today's aircraft. And while they are productive, the machines usually take up a lot of room and come with hefty price tags — reasons keeping many smaller shops from entering the lucrative field of aerospace contract machining. However, a new series of machining centers offers the little guy a foot in the aerospace door.

Instead of a gantry-style machine with multiple vertical spindles, Makino's MAG machines are horizontals with single spindles. The configuration makes the machines smaller and a little more affordable than a gantry-style machine. But are the MAGs as productive? According to Makino, the horizontal configuration itself, along with some innovative machine components, not only provides shops with the lowest possible manufacturing cost but also increases their productivity and part quality while reducing tooling and fixturing costs.

In some instances, end users have reduced labor by up to 75% with a MAG machine as compared to a traditional gantry. According to Mark Waymouth of Makino's Aerospace Group, the MAGs do this by achieving 3X the metal-removal rate with the one spindle and keeping that spindle in the cut 3X longer than a multiple-spindle gantry machine. "Amazingly," adds Waymouth, "the MAGs easily reach a 75% spindle-use level as compared to that of a typical gantry machine, which is about 25%."

At the heart of a MAG machine's productivity is Makino's proprietary spindle design. The 80-hp (60-kW), 30,000-rpm spindle delivers a ±107.5° range of motion in the A axis and infinite rotation in the C axis without having to stop and reverse the rotation to unwind power cables. What makes this possible is a slip ring that transfers signal and power to the spindle without cables or windings. With the MAG's spindle head, shops no longer have to run a blending operation to smooth a workpiece surface where a tool re-engaged after a cable-unwinding procedure.

For rigidity, the spindle houses two 75-mm cylindrical roller bearings in front and one in back, along with two angular-contact ball bearings. The large cylindrical roller bearings provide plenty of contact, so shops can push the spindle harder as compared to a traditional spindle, which may have only ball bearings. In roughing applications, the MAG spindle easily handles the machine's average metal-removal rate of 144 in.3/min and its maximum of 350 in.3/min

Another special feature of the MAG spindle is core cooling. Oil runs through the center of the spindle and spreads to the outside of the spindle jacket. By keeping the spindle cool in such a fashion, Makino can preload the bearings much higher, allowing the spindle to run at 30,000 rpm all day long, says Jason Calimlim, product manager for the MAG series.

In addition to its spindle and A/C-axis spindle head, the MAG's chip management, toolchanging, and part-handling capabilities contribute to its high productivity. Because MAG machines are horizontally configured, operators don't have stop the machine, climb onto its platform,and sweep off accumulated chips. Chips fall away from the workpiece and directly into a chip conveyor on the MAG machine. This feature also improves part quality and tool life. "On traditional gantry machines," says Calimlim, "shops are often recutting chips that don't fall away. As a result, both surface finish and tool life suffer."

For toolchanging on multiple-spindle gantries, operators usually switch tools manually and must keep track of what tool goes into which spindle, says Waymouth. MAG machines have onboard tool storage and automatic toolchangers that supply the machine's spindle with a tool in 8 sec. As a plus, having only one spindle lowers tooling costs because it's less expensive to tool a single spindle as opposed to a machine with more than one, adds Waymouth.

Also, tool setting is more intense on a multiple-spindle gantry—mainly because it is virtually impossible to get all the tools to cut exactly the same, so hand blending is necessary. On MAG machines, automatic tool-length measurement systems adjust tool lengths to eliminate handblending requirements.

According to Makino, the key to efficient part handling is doing as much of it as possible in "masked time," meaning while the spindle remains cutting. MAG machines feature work indexers that do just that. The indexers, located at the fronts of the machines, rotate 180° to load the next workpiece while simultaneously unloading a finished one. Parts enter the work envelope in the vertical position, and the process takes between 2 and 3 min.

For large aerospace parts, Makino offers a horizontal load station. Operators load/unload parts that are lying flat. The station then picks up the part and presents it to the work indexer in the vertical position. There is also an available automated workhandling system, called Module MMC. It lets shops store parts, fixtures, tooling, and programming off-line. Jobs are set up once and can run at anytime—even between other jobs.

When it comes to fixturing, says Waymouth, MAG machines reduce cost because of their single-spindle configurations. The machines require one fixture per part as opposed to the multiple identical fixtures needed with gantrytype systems. In addition, the MAG's highspeed machining capabilities and low cutting forces make it possible to machine some parts with no fixturing whatsoever. Shops use a simple picture frame to surround the part.

MAG machines get their fast cutting speeds from Makino's SGI.3 high-speed motion control-working in unison with the machine spindles. "This system goes beyond just a lookahead control," comments Calimlim. "It takes into account the duty rating for the motor and servos for optimum acceleration/ deceleration and feedrate across an entire cutting path."

The whole family

Currently, the five members of the MAG family of machining centers are the MAG3, MAG4, MAG7, MAG10, and MAG16. Axis travels in X are the main difference between models. The MAG3's X-axis travel measures 3 m, while its Y is 1.5 m. The Y-axis travel for the rest of the machines in the series is 2 m with an optional 2.6 m available. The MAG4's X is 4 m, the MAG7's is 7 m, and on up to the MAG16's 16-m X.

The Makino MAG4 is one of five horizontal machining centers geared for aerospace work.

A column design supports the MAG machine X and Y axes. For the MAG4, 7, and 16, linear motors provide high-speed and quick response in the X axis, while core-cooled ballscrews move the Y and Z axes.

Footprints of the machines measure 452.8 X 295.3 in. for the MAG3, 393.7 X 472.4 in. for the MAG4 (with pallet loader), and 531.5 X 472.4 in. for the MAG7 (with pallet loader). The MAG10 and MAG16 measure approximately 630 X 393.7 in. and 866.1 X 393.7 in.