Everyone's talking linear motors for high speed machining, but what are the roadblocks to total acceptance of the technology?

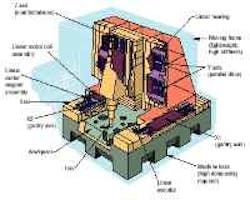

An illustration from Anorad Corp. shows how linear motors are integrated into a vertical machining center.

Linear motors, such as this Baldor slotless one, are finding greater applications in high speed machining centers.

Kingsbury's newest linear motor machine, the Cyber-Cell 2, accelerates up to 1.6 G and has speeds up to 90 m/min.

Accelerations up to 1.4 G and speeds of 120 m/min are possible on the XHC 241 machining center from Ex-Cell-O. The company offers a choice of two spindles, either 16,000 or 24,000 rpm.

Linear motors are not a new technology, but acceptance has been slow in the machine tool sector. Although some builders have been using linear motors for more than 10 years, many others are cautious, opting instead for the tried-and-true combination of ballscrews and rotary motors. Even those companies that have built linear motor machines are quick to point out that they aren't practical for every machining job. However, these builders also say that if the application fits, no other machine can beat them for speed—especially in acceleration and deceleration.

The first machine tools with linear motors came out of a collaboration between Ford Motor Co.; The Ingersoll Milling Machine Co., Rockford, Ill.; and Anorad Corp., Hauppauge, N.Y. Ford wanted machines with speed and precision, but it also wanted flexibility, which its transfer lines could not supply.

The result of this project was Ingersoll's first High Velocity Module (HVM), a machining center using high force linear motors. It also featured a radically new structure, the result of finite element analysis, and a fluid-bearing hydrostatic/hydrodynamic spindle. Since then, Ingersoll has introduced both the HVM 600 and 800 to the marketplace, and Ford is still a customer.

Other automakers and industries—most notably aerospace— are now exploiting the benefits of linear motors. Business is also hot in Europe, particularly in Germany, France, and Italy, according to a number of machine builders and motor manufacturers. Says Dr. Boaz Eidelberg, Anorad's director of linear motor business development, "Although this technology is in its infancy, pioneering corporations such as Ford, Chrysler, and Mercedes, as well as Boeing and British Aerospace are spending hundreds of millions of dollars in promoting it."

Aerospace manufacturers use linear motors because they not only handle the high speed cutting of aluminum parts, but they eliminate backlash and provide good contouring and interpolating capabilities. All these benefits, explains Ingersoll's John Osborn, manager of engineering for the Heavy Machine Division, make linear machines well suited to aerospace applications, especially when it comes to machining monolithic, thin-walled parts.

What is a linear motor?

In perhaps the simplest terms, a linear motor is an open and laid-flat version of a rotary motor. It has two elements—motor and slide, according to motor manufacturer Kollmorgen, Radford, Va.

A significant difference between the two, notes Norman Bleier, engineering manager with the Machine Industry Business Unit of Siemens Energy and Automation Inc., Elk Grove Village, Ill., is that, in a rotary motor, torque is produced by the interaction of magnetic fields. The conversion of (rotary) torque to (linear) thrust is accomplished using a mechanism, most commonly a ballscrew and nut. The magnetic field interaction of the linear motor produces direct thrust to eliminate intervening mechanical linkages.

Linear motors come in two types: synchronous, which employs rare-earth permanent magnets, and asynchronous, or induction, which uses electromagnets. In machine tool applications, synchronous linear motors are preferred, because they exhibit the highest cutting force per unit area given the same temperature rise, according to Baldor Electric Co., Santa Clarita, Calif.

Unfortunately, permanent magnets have a number of disadvantages. They require careful handling due to high magnetic attraction, are more difficult to install, and attract ferrous chips even when the machine is shut down. They also tend to cost more.

Asynchronous motors, on the other hand, have no problems with ferrous materials, but offer less thrust and speed.

Kingsbury Corp., Keene, N.H., has used both linear motor types. Its first linear motor machine, the Cyber-Cell, used an asynchronous linear motor. Says Dennis Done-gan, manager of systems engineering, "At the time, we felt asynchronous was the solution because of issues concerning permanent magnets, mainly chip control." However, when the company introduced the Cyber-Cell 2, it opted for permanent magnets because they were lighter and more powerful. Kingsbury now feels that its future lies in the permanent magnet approach.

Ex-Cell-O Machine Tools Inc., Sterling Heights, Mich., offers both types of linear motors on its XHC 241 machining center, an open (synchronous) motor and an encapsulated (asynchronous) one. According to Glenn Chagnon, account manager, Germany and Southwest region, "When you get into a bi-metal setup, where you might have an aluminum as the parent metal and a liner—maybe a steel bushing or a cast iron piece needing a light cut—you would use an encapsulated motor to keep metal particles out of the motor. But, for an all-aluminum part, an open motor is preferred."

Linear thinking

No matter what type is used, linear motors provide several significant advantages over rotary motor/ballscrew configurations. "In principle, linear motor machines are an order of magnitude faster, smoother, and simpler than their rotary driven counterparts. Therefore, they can generate parts in much shorter time, with much higher quality, higher accuracy, and considerably lower downtime," says Dr. Eidelberg.

Motor and drive manufacturer Indramat Div. Mannesmann Rexroth of Hoffman Estates, Ill., agrees, reporting that in terms of speed, acceleration, and accuracy, today's top-of-the-line, high-speed ballscrews have maximum speeds of 40 to 60 m/min, acceleration to 1 G, and repeatability of 0.01 mm. However, a permanent magnet linear motor can operate many times faster, at speeds up to 600 m/min, provide acceleration up to 10 G, and repeatability of 0.0001 mm.

In addition, the dynamic stiffness of a linear motor is several times greater than that of a rotary motor, which leads to a better part finish. A rotary motor can obtain force, torque, and velocity, but gearing and windup of the necessary mechanical components introduce positioning error into the system, reports Indramat.

Dr. Eidelberg says that with linear motors, the only limit to total system accuracy and repeatability is the machine's sensing device and the bearings of the positioning system. In rotary driven systems, there are additional factors that affect performance, including backlash, hysteresis, lost motion, and jitter.

Linear motors also provide extremely smooth motion, since they have no contacting surfaces. By contrast, ballscrews are not as smooth due to the vibrating nature of the balls entering and exiting the ball nut raceways.

In addition, long axis travels are not a problem with linear motors because the magnets that make up their assemblies can be easily joined together to form any length motor. Screw driven systems, on the other hand, have critical speed limitations, low stiffness, and higher inertia with added length.

Another advantage to linear motors is that they have no mechanical parts in contact with each other, thus eliminating friction and wear. Dusan Senic, manager, controls for Ex-Cell-O, explains: "A rotary motor transfers motion through some kind of a gearbox through the ballscrew, which can lead to friction and some power loss. Linear motors have fewer parts, so there is less friction and fewer mechanical restrictions."

As for motor wear, Jim Koontz, president and CEO of Kingsbury, says that the life of a linear motor is about 5 3 greater than that of a ballscrew system, which has implications relative to the maintenance of a machine. "Ballscrew life is about 8,000 hours," he estimates, "which means you're tearing down at least 5 3 more to replace ballscrews. In comparison, we expect linear motors to last roughly 50,000 hours."

So, if linear motors sound like the next best thing to sliced bread, why aren't all machine tool builders converting? Well, some of the reasons center around the applications that linear motors can and cannot handle, cost considerations, and mechanical limitations.

When are linear motors not so hot?

The application really determines whether or not a linear motor is right for the job. For example, says Ex-Cell-O's Chagnon, these machines really shine when it comes to high speed cutting of aluminum. "If you concentrate, for example, on cylinder blocks of cast iron, linear motors really wouldn't be advantageous. But if you wanted to machine an aluminum cylinder block, then, absolutely, use linear motors." However, he continues, applications are limited as far as steels. "The density of steel does not really allow for the high speed penetration rates that linear motors can produce, so you're really not utilizing the motor's maximum speed."

Jean-Paul Bugaud, vice president of machining for Renault Automation in France, agrees that rough milling of iron, steel, or Inconel may not be the forte of the linear motor machine tool. But, he adds, Renault machines have tackled cast iron cylinder blocks. "As long as the machining does not require more than 400 daN of thrust and 35 mN torque, you can use the Urane 20 or 25," he says.

If one does want to machine ferrous materials, a light cut may be necessary, says Larry Forbus, product development engineer at Kingsbury. For the most part, though, he reports, applications for Kingsbury's Cyber-Cell 2 involve nonferrous material.

Cost is another factor that can make linear motor machine tools less attractive. The machines typically sell for 10% to 30% more than a ballscrew machine. Power consumption is also higher. But, on the plus side, says Eidelberg, linear motor machines can be expected to have at least double the productivity. He does note that this figure depends on the number of shifts and the duty cycle. He also estimates that, on the average, the linear motor machine is about 5 3 more cost effective than a ballscrew one.

Cost should become less of a problem, notes Donegan of Kingsbury, "as more and more players enter the market—Kollmorgen, Siemens, Anorad/Allen-Bradley, Indramat, GE Fanuc—and as the competition gets healthy, you are going to see the motors come down in price."

However, the cost of these machines isn't all wrapped up in the price of linear motors. You simply can't slap one on an existing machine tool and expect it to work. Design changes to the machine structure, spindles, and more are necessary, says Ingersoll's Osborn.

"High performance machine tools require structures specifically designed to optimize the use of linear motors," comments Kingsbury's Forbus. "Elements that move, such as columns and slides, must be as light as possible, yet stiff at the same time. They must be analyzed for deflection under acceleration and high stress areas. Machine bases must be designed for minimum deflection under static and dynamic loading. This is done with finite element analysis. A modal analysis must be performed on the major structural elements to determine the natural frequency and harmonics to avoid resonance from the motors, spindle, and cutting tools."

Other disadvantages of a linear motor machine include lower thrust and little intrinsic dampening as compared to a ballscrew configuration, says Ex-Cell-O's Senic. Linear motors also generate a lot of heat, so cooling systems usually have to be integrated into the machines.

Finally, notes Dr. Eidelberg, linear motors can literally take off with "jet-engine like power" thus presenting hazardous conditions as well as potential damage to equipment and property, unless properly controlled with safety features such as dynamic braking, positive brakes, hard stops, and possibly redundant sensors. Linear motors also have no mechanical advantage like their ballscrew counterparts, he says, and hence, must be counterbalanced for most vertical applications.

A look into the crystal ball

Linear motor machine tools seem to have a bright future, according to estimates based on the Economic Handbook of Machine Tool Industry U.S. Consumption figures. About 3,000 linear motor machine tools will be sold in 2005, up from only 300 sold in 1997. Dr. Eidelberg and Anorad estimate that when linear motors reach a commodity level like rotary motors, in about 10 years, they will constitute about 20% of all CNC axes, a figure backed up by the folks at Siemens.

But where linear motors may not make inroads for years to come is low production, toolroom equipment. Two reasons for this are the high cost of the linear motor machines and the fact that rotary-based systems can usually tackle heavier cuts. Also, the vast majority of machine axes do not require the high speed and dynamic response advantages offered by linear motors.

Chris Vaniglia, drives and motors product manager for Vickers Electronic Systems, Lebanon, Ohio, believes that eventually machine tools will widely use linear motors, but he doesn't think it will be anytime soon. "The reason being that the most efficient motors, the permanent magnet ones, need a high degree of protection from the cutting process in terms of guarding or integration into the ways to avoid contamination from coolant and metal chips. So machine builders have to design rather complex structures, which are not always economical unless it's a high-end machine. In the machine tool market, the environment is harsh, the structures are big, and the forces are large, so the technology will take longer to emerge."

In the meantime, other developments in the machine tool industry are proving to be worthy alternatives to the linear motor. Vaniglia brings up roller ballscrews, for example. "Machine tool builders," he notes," have reached 1.5 G with roller ballscrews, which is close to a linear motor spec. The advantage of the roller screw is that while it's more expensive, you don't have to redesign the whole structure to get it in the machine."

Competing technologies may also be better for vertical axes due to gravity and power failure considerations. This is explained by Keene, N.H., based Precitech, a manufacturer of ultra precision machine tools for production of lenses, mirrors, optical elements, and mechanical components used in the semiconductor production equipment, consumer electronics, automotive, and defense industries.

Says company President and CEO David William Davis, "Linear motors do not work well when mounted in a slide that is in turn mounted vertically. The reason for this is that a counterbalance is required. This counterbalance generates a level of mechanical noise that would not normally be a problem for high precision or standard type machines, but for an ultra precision application, the noise becomes intolerable."

Otherwise, he states, linear motors are a must for ultra precision machining, noting, "The surface finish required for our customers' types of parts can be obtained at feedrates up to 4 3 faster than those finishes obtainable with a traditional rotary motor/lead screw type system."

But as far as traditional metalworking jobs are concerned, most companies agree the future lies in high production applications. For example, Kingsbury expects that within the next 10 years, about one-third of all new machine tool purchases for mid to high-volume production will be linear motor equipped.

In addition, the company believes that linear motor machines will prompt many new tooling breakthroughs. "This is tied to the accuracies that can be obtained while interpolating with linear motors," says Coughlin. "They will further push the development of new spindles, new methods of tool change, and new chipbreaking methods."

Linear motors on the shop floor and ready to go

According to French builder Forest Liné, its Linear Minumac is as much as 33 more rigid than comparable ballscrew machines, which provides good accuracies and surface finishes.

Precitech's Nanoform 200 uses MTS Automation's MaxPlus linear motors, which are designed for critical motion applications.

Mitsui Seiki's 3GEN grinder has a linear drive motor on the Zaxis. The company reports that the machine's positioning accuracy is ±0.000028 in.

A number of companies are producing high speed machining centers with linear motors: Ingersoll, Kingsbury, Ex-Cell-O, Grob Systems, Precitech, Renault Automation, and Forest Liné are just a few.

Ingersoll's HVM 600 and 800 are high velocity machining centers with linear motor axis drives that produce speeds to 80 m/min and acceleration/deceleration rates of up to 1.5 G. The machines feature a box-in-a-box design and a fluid-bearing, 20,000-rpm hydrostatic/hydrodynamic spindle. Users can choose either Indramat or GE Fanuc motors and drives.

The Cyber-Cell 2, from Kingsbury, has acceleration rates up to 1.6 G, a speed of 90 m/min, and a standard 18,000 rpm spindle. The machining center can be used as a stand-alone independent unit, within a U-shaped cell, or in an in-line flexible transfer system. The machine's positioning accuracy is 0.003 mm, and its repeatability is ±0.001 mm. Users can select either Allen-Bradley or GE Fanuc controls; the motors are made by Anorad.

New from Ex-Cell-O is the XHC 241 machining center, which accelerates up to 1.4 G and has speeds of 120 m/min on X, Y, and Z. Its positioning accuracy is 0.003 mm. The company offers a choice of two spindles, either 16,000 or 24,000 rpm, and the system can be equipped with synchronous or asynchronous linear motors from Siemens or Indramat.

Grob Systems Inc., Bluffton, Ohio, has developed a horizontal machining center, called the BZ 600 L, with linear motors and a 15,000-rpm spindle. It features axis travels of 800, 630, and 550 in. in X, Y, and Zand accelerations of 8, 12, and 20 m/sec, also in X, Y, and Z. The company reports positioning tolerances of 0.010 mm from the BZ 600 L's linear motors made by Siemens.

Precitech's Nanoform 200 is a two-axis, ultra precision contouring machine that uses diamond tools. The machine can cut optical quality surfaces in a wide range of nonferrous metals, crystals, and polymers. It can also be equipped with a high speed grinding attachment for manufacture of small lens molds in non-diamond machinable materials such as tool steel, silicon carbide, and ceramics. Its linear motors, made by MTS Automation, New Ulm, Minn., provide speeds from 0.001 to 3,000 mm/min.

Two French firms are also turning out machining centers with linear motors. The first, Renault Automation, produces the Urane 20 and 25. On these machines, all axes are moved by two linear motors. The speed of both machines is 80 m/min, and both have an acceleration of 1.5 G. The Urane 20 and the 25 have a 20,000-rpm electric spindle as standard and a 24,000-rpm spindle as an option. The control is a Siemens 840 D.

The other French builder, Forest Liné, will introduce its Linear Minumac at the upcoming EMO show in Paris. Designed to machine large parts, the machine comes with vector-controlled HF spindles with speeds from 16,000 to 40,000 rpm. The Linear Minumac's feedrates go as high as 60 m/min, and its accelerations reach 0.5 G. Linear motors are also turning up in systems besides machining centers. They are particularly suited for applications with low mass and process forces, such as laser cutting and some grinding operations.

Linear motors are also cropping up in plasma cutting machines, coordinate measuring machines, waterjet cutters, EDM systems, and rapid prototyping machines, as well as saws, punches, and presses. Among builders showcasing the Siemens Simodrive 1FN1 linear motors at EMO '97 were Trumpf, Synova, and Balliu (laser cutting); Landis, Mitsui Seiki, Jung, and Saimp (grinding); and PCI and Kirby (special machine/other applications).

Mitsui Seiki Inc., Franklin Lakes, N.J., has a grinder with a linear drive motor on the Zaxis. Called the 3GEN, this CNC grinder is built for maximum rigidity and stability, with a fully ribbed bed that deflects distortion as well as hand-scraped guide-ways. The machine's spindle motors top off around 90,000 rpm, and its positioning accuracy is ±0.000028 in.

Linear motors are also employed by Landis Gardner, Waynesboro, Pa. Its 3L Series CNC crankpin grinders and its 3L CNC camlobe grinders, which are used to generate complex forms, are providing close tolerances, accurate wheelhead positioning, and high acceleration rates. The company says that the grinders have proven extremely accurate in grinding contours, especially complicated re-entrant contours.

From concept to reality

Hardinge's Concept 2000 machine, here with its covers off, was exhibited at IMTS.

A closeup shows the Concept 2000's hydrostatic spindle and top plate. Gang tooling will be an important part of the future technology because the tool doesn't move far from the workplace to do the cutting from one operation to the next, reducing setup and cycle times. The attachment with a hose going to it is for live tooling — hydrostatic live tooling with a 20,000 rpm capability.

One company that is taking a hard look at linear motor technology is Hardinge Inc., Elmira, N.Y. The company displayed a concept machine at IMTS that not only sported linear motors, but also a hydrostatic bearing spindle, hydrostatic guides, a GE Fanuc PC-based control, and a Harcrete polymer base. Named Concept 2000, the machine traversed at rates of 3,000 ipm and accelerated at 3 G.

A unique challenge on the Concept machine, says Terry Sheehan, manager, Mechanical Design & Analysis, was combining the linear motor with the hydrostatic guideway system. He explains that the problem was in compensating for the high attraction force of the magnets teamed with the typical gravity loads that are found on a guideway system. "The deflection of the slide alone under that attraction force changed our hydrostatic geometry," he says. Finite element analysis studies that were conducted clearly outlined the required geometry changes.

Sheehan also notes that linear motors are enormous electrical noise generators that can cause problems with feedback devices. However, he is quick to point out, advances in feedback devices are making them more immune to that noise.

Although Hardinge currently does not incorporate linear motor technology in its standard product line, this technology is being closely monitored for future machine designs. Says Dan Soroka, vice president of engineering, "For many applications, we don't think linear motors are yet a mature enough technology for Super Precision tolerances held on Hardinge products. I think there is a place for them, and I think the technology is going to continue to develop. I also believe we will see them more frequently in metalcutting and material handling applications—as the volumes increase, the technology improves, and the cost of using the systems decreases."