Sawing that's more like milling

With advanced features, bandsaws hold tolerances and leave finishes that rival an actual machined surface.

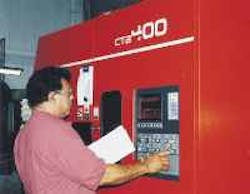

A CTB-400 bandsaw's CNC selects the best cutting parameters based on operator-entered data concerning material type, size, and shape.

With an antivibration guide-roller arm and automatic guide-arm positioning, a CTB-400 adapts to varying surface footage to cut square and smooth.

CNC bandsawing eliminated a 2,000-hr/year preparatory milling operation at Dana Gresen Hydraulics Div.

Dana Gresen Hydraulics Div. doesn't square-up its parts before machining anymore. That's because the rough pieces come off the band-saw accurate enough to skip a preparatory milling operation and go directly to a machining center vise. Not only that, the saw-cut surface is smooth enough to leave 'as is' for a completed part.

Besides the elimination of a 2,000-hr/year milling operation, the Sarasota, Fla., hydraulic valve and pump manufacturer also has less scrap, saves about 84 bars of material annually, and is enjoying a 50% increase in productivity.

An Amada Cutting Technologies Inc. (ACT) CTB-400 CNC bandsaw currently cuts all of Dana's material, approximately 120,000 pieces a year, mostly out of 6061 T-6 aluminum, 12 L14 steel, and 65-45-12 ductile iron. A number of the saw's standard features enable it to hold precise tolerances, automatically select the best cutting parameters, cut almost perfectly square, and adjust its own feedrate for a smooth surface finish.

The self-diagnostic CNC lets Dana operators program and preset controls for exact runs, avoiding accidentally changing speed, feed pressure, or part length. Using what ACT calls Optimal Cutting Control, the computer selects the best cutting parameters based on operator-entered information concerning material type, shape, and size. Included are 229 factory-installed material specs and the room to program up to 100 additional custom materials.

Cut squareness is accurate to within ±0.001 in./in. of diameter. A band-deviation detector monitors through the entire cut to keep parts square. Variable speed settings, not an option on the old circular saw, also improve squareness and finish by allowing the presetting of different speeds for a single cut.

The blade eases into the cut at a lower surface-foot rate to assure a straight start, then, once into the part, it speeds up. Towards the end, it again slows for a smooth transition out of the piece. Operators choose a tolerance for squareness, and the CTB will hold it. If for some reason it can't, the saw will make three attempts to correct itself by automatically adjusting the feedrate. If adjustments prove un-successful, the machine shuts down before ruining workpieces.

An anti-vibration guide-roller arm, working in unison with the optimum-cutting control and band deviation detection, delivers cut surface finishes in the 62-rms range. According to Eric Cross, manufacturing-area supervisor at Dana, the company's old circular saw cut a surface between 125 to 250 rms. Now, cut parts have finishes at 60 to 80 rms. Company specs call for 120 rms.

The old saw cut one bar at a time, so running multiple bars or tubes of stock simultaneously on the CTB saves time.

The saw's table size accommodates stock up to 16 11 /16 in. 2 , and the clamping system holds 6 to 12 bars of Dana's material, ranging from 1-in. 2 to 10-in. 2 with various cut lengths. The antivibration guide-roller arm and automatic guide-arm positioning, together with the o p t i m u m --cutting controller, lets the CTB adapt to varying surface footage encountered when sawing more than one bar.

Most carbide blades don't take shock or vibration well. A loosely set guide-roller arm can lead to a damaged blade and scrapped part. The CTB's anti-vibration guide-roller arm keeps blades snug for longer life. Dana's blade use dropped from 10 a month to about three.

The company also saves stock by using the auto trim-cut feature. At the beginning and end of every bar of stock, the CTB trims off an unusable portion according to operator-set dimensions to as little as 0.600 in.

According to Cross, current savings are not the product of the CTB being faster than the old saw. The production bottleneck was the secondary milling operation, which was needed because the old saw didn't cut square and left a rough surface. "At the end of an hour, both the circular saw and the CTB would produce the same amount of parts, but the old saw involved more labor—loading one bar at a time—and was not as precise as the new saw," says Cross. To evaluate a sawing operation, advises Cross, shops should focus on blade life, cycle times, and the amount of babysitting the equipment needs during a shift.

Cutting comparison"Steel mills, steel service centers, and any company doing a lot of high volume with aerospace alloys or hard materials will benefit from the speed and cut quality of a CTB-400," says Amada Cutting Technologies Inc. president Toshi Ichimura. He substantiates his claim by presenting the results of a cutting comparison between the CTB-400 and conventional bandsaws. In tests prior to its release, the CTB slashed the cutting time for a 7-in.-diameter, 1045 steel part to 46 sec and produced a finish of 62 rms. The same cut on a conventional saw took an average of three minutes and left a 125-rms finish. For a 9-in. round 416 stainless steel part, cutting time dropped to 3 min with a 62- rms finish as compared to 15 min and a 125-rms finish. Lastly, a conventional bandsaw had a production rate averaging 10 in. 2 /min cutting 7 1 /4-in.-diameter, 4130 steel stock. A CTB-400, for the same material, saws at 30-in. 2 /min. |