A New Method for Detecting Lobing

The LaserLinc. Lobing Detection System is a real-time tool for detecting and eliminating lobing problems. It can identify 3-, 5-, 7-, 9- or 11-lobing on centerless ground products as they exit a grinder.

LaserLinc, a manufacturer of non-contact laser and ultrasonic measurement systems, has developed an system for lobing-detection in centerless grinding. Lobing is deviation from roundness on a centerless ground part, a critical issue for any shop that produces or uses centerless-ground product.

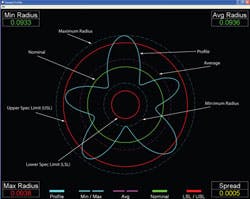

LaserLinc’s Lobex Lobing Detection System is a real-time tool for detecting and eliminating lobing problems. It can identify 3-, 5-, 7-, 9- or 11-lobing on centerless ground products as they exit a grinder. The system also can be used for offline inspection.

The developer states that, unlike testing with tri-mikes, which provide inconsistent and err-prone Lobex provides “repeatable and reproducible” data. And, the Lobex software can identify higher-frequency lobing; Tri-mikes under-report 5-lobing, and compounding the error, 5-lobing in a product masks tri-lobing.

Using a Lobex system, an operator can identify lobing as it begins and make the necessary adjustments to the grinder to bring the part back into spec. The system combines a high-speed 3-axis laser scan micrometer with a proprietary software package.

The software package includes polar charts, trend charts, data logging, alarms, SPC, customizable reports, and LaserLinc’s support.