There are six aspects of grinding processes and apparatuses that, thanks to new technology or practices, now are delivering double-digit productivity gains. Used in combination, these factors often deliver multiple productivity gains. In some instances, almost unbelievable (if not verifiable) economic results are achieved. In a global economy, with cheap labor available but at great distances, and complicated by cultural barriers, time zones, and long supply lines (requiring high finished goods inventory), adopting these improvements will help manufacturers to minimize or overcome their offshore competitors’ cheap-labor advantage.

First, there are computerized advances to process planning that allow multi-tasking in grinding. Second, there are advances in grinding wheels, from smaller sizes capable of higher speeds to better material removal rates (MMR) and longer service life. Third, there are improvements to fixturing schemes. Fourth, there are advances in coolant applications that transfer heat better from the workpiece, to increase material removal rates and avoid thermal damage to the workpiece material. Fifth, there are advances in application software that help to address normal processing problems and to assist in the use of available labor. And last, through long-term use of ISO-9000 principles, machines are becoming exceptionally reliable.

Multi-tasking

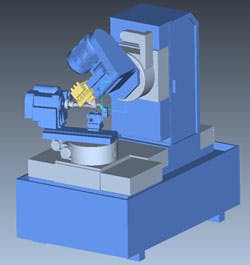

Let’s take these options in order of economic impact: Using five axis machines it is now possible to consolidate what previously had been several set-ups in several stand alone machines, into one set up in a single multi-tasking machine. So, one machine can perform all the operations to complete a part in one set-up.

Designing this capability involves CAD/CAM and a virtual process, using modeling software like Vericut. First, each part feature to be machined is analyzed, followed by the wheel forms required to create them. A sequence of operations is prioritized. Then, fixtures are designed and sequenced. Several individual part-feature wheel forms can be consolidated into fewer wheels, and used in wheel packs. This capability requires specially designed fixtures that can withstand side loads. The final benefit is a single datum for all features, so it’s easier to produce the interrelated features to tolerances so difficult when using sequential machines because of tolerance stack-up issues.

This approach adds up to a truly "0" scrap process — the No.1 goal for manufacturing quality. By substituting a single part-flow process, this method avoids the batch lots required for sequential machine processes that can result in high scrap rates. Another benefit is reduced throughput time for the entire production cycle. Instead of days or weeks to sequence batches through multiple machines and multiple set-ups, the parts are complete as they exit the machine, lowering process inventory dramatically.

Wheels

The basic choices among grinding wheels are conventional abrasive (CA) wheels (in either continuous dress or intermittent dress), or superabrasive (SA) in electroplated CBN (EPCBN) or vitrified bond CBN wheels. EPCBN does not require dressing, and vitrified CBN requires only infrequent dressing. In the past, the choice was CA wheels that wear out rapidly. Therefore, for utility, CA wheels are large in size, but this limits the number of features that can be accessed at a time and outsizes the machine design, driving up machine cost and floor space requirements. The CA wheels wear with each turn, requiring compensation, which is a source of variation, and requires a skilled operator.

CA wheels require frequent changing because of loss of diameter, reducing their productivity. Also, the CA wheel requires either intermittent or periodic dress to hold form, which leads to more nonproductive time. They produce a lot of waste swarf. They take up a lot of floor space.

Product changeovers for CA production lines are measured in hours, or more usually in shifts, which is more non-value adding time. Normally, CA wheels are only partially used before disposal, especially when a small and a large wheel are used at the same time, which drives up abrasive cost. The amount of CA wheel consumed as a percent of the material removed ("G" ratio) is relatively low. Because the CA wheels are glued-together materials, they have a speed limit before they explode, which governs speed for material removal. So bigger is better for CA wheel surface speeds, but makes for larger machines, longer changeover times, and more difficult handling. Less swarf is created using SA wheels and they require less storage space. Actual SA per part abrasive costs are less than CA.

SA wheels are metal-core products with a layer of abrasive applied to the Outside Diameter (OD), in either plated — not requiring dressing — or vitrified bonded with infrequent dressing. SA wheels have dramatically higher "G" ratios compared to CA wheels giving them some highly beneficial characteristics.

CAD/CAM and virtual design capability allow for better fixture utilization, but it’s still possible for some parts to be chucked once and finished completely.

Machine Application Visual Interface Software (MAVIS) can be used to compensate for spring detected by the CMM without stopping production.

Because the SA wheels do not appreciably wear part to part, the wheels can be smaller than CA, run at much higher surface speeds, and last longer before change out. Because they are smaller, more wheels can be mounted side by side in a wheel pack. SA wheels can run hundreds or thousands of parts before being re-plated (reused). The need for wheel dressing (and a skilled operator) is eliminated. And, instead of many machines in sequence, one machine and wheel pack can do the complete part in a "bumble bee on a flower" like action, to address all the features to be ground in a single part per cycle.

While the actual MMR rates of SA wheels may be similar to CA, major economic advantages come from the single datum (reduced scrap and throughput time) and faster surface speeds of SA compared to CA wheels. The use of more tangential force than normal force applied to the workpiece lowers the risk of thermal damage. A SA wheel takes a chip removing heat from surfaces, rather than forcing heat into the part like a CA wheel.

Unlike CA wheels, electroplated SA wheels can grind in grooves. CA wheels cannot grind effectively into grooves because of wheel wear, so a milling operation is required instead. Thus, using SA wheels, a separate operation can be eliminated, i.e. consolidated into the grind process, thereby streamlining the overall process.

Still, today there are many new technology "hybrid" wheels available. New technology CA wheels have higher "G" ratios, in between traditional CA and SA. Often they use ceramic bonding agents. Most importantly, because of the lower wear rates, these wheels can be made smaller than CA wheels and can be intermittently instead of continuously dressed. That means they can be either used in wheel packs, or can be changed in a few minutes, or used with an automatic tool changer (ATC).

Smaller hybrid wheels allow an ATC to avoid down time to change over of large diameter CA wheels by hand. Instead of a massive continuous dresser, these Hybrid wheels can use a "static" dresser, smaller and less expensive than a roll dresser. The longer grain in the new hybrid CA wheels allows for better coolant effect and higher materials removal rates (MMRs).

Fixture sequencing and construction

The CAD/CAM and virtual design ability mentioned above allows for better fixture utilization, especially using multiple progressive fixtures within a machine. Still, sometimes a part can be chucked once and then finished completely.

Compared to multiple-sequential batch processing for parts, this is an extraordinary advantage for quality and throughput time. Sometimes more complex prismatic parts can be accommodated by multiple fixtures on a table in one machine, and then progressively moved through a series of grinding operations on fixtures to complete all features of one part to the same datum. It’s possible for weeks or days of part processing to be reduced to minutes.

Using multiple wheels and multiple surfaces on a wheel in a pack of wheels, as mentioned above, allows that "bumble bee on a flower" process, completing all features in a single chucking, and eliminating changing wheels or changing machines.

For example, complete shrouds can be done one part per cycle, leading edge, trailing edge, and slash faces. Fixtures are designed for side wheel loads and taking the force of the heavier material removal rates.

Coolant and application

For CA grinding, the conventional wisdom has favored higher volumes of flood coolant per HP used over directing that coolant into a specific grind area. Similarly, less attention has been focused on the actual heat transfer capability of the coolant. For SA grinding, attention has centered more on matching the velocity of the coolant speed to the wheel speed, and on controlling the application of the coolant stream to the grind zone. Much work has been done along these lines to design coolant nozzles specifically for better laminar flow and pointing improvements. The result is a coherent stream.

Still, coolants contain a lot of entrapped air, functioning like Swiss cheese between the wheel and work. Now, there is more attention on eliminating aeration from the coolant systems through better plumbing, use of line conditioners, new coolant nozzle designs, and better filtration system settling. These efforts work to eliminate the entrapped air that undermines the heat transfer capability of the coolant. Dramatic improvements to MMR are being achieved without thermal damage to the material.

Application software

The evolution of application software has been one of the biggest economic benefits, assisting operators to make better parts and reducing the time spent waiting for programmers to make simple process changes to deal with reoccurring process anomalies. Also, with the complexity of many processes, more user-friendly interfaces have been devised to allow use of "available labor" personnel through computer prompting to follow defined procedures. Lastly, manufacturing plans can be stored and updated on the machine for quality control purposes.

Machine shops are trending away from the habit of hogging parts from solids, and instead for them to use of investment cast or forged raw materials. Investment castings are sort of like exoskeletons with a hard shell or casing left on the metal. When these parts are first machined, internal stresses can be released that cause the parts to "pretzel," i.e. to lose their shape. For example, for shrouds with radial grooves or vanes, a rough pass can relieve stress and cause the part to spring out of shape with a radius that’s too deep or too shallow, or with an incline or decline. CAM programs fail to allow for operator compensation. New software allows operators to compensate for part distortion and the daily reality of residual stress release.

(AM040510_Huffman IGT_6.jpg)Further, some CA grinding machines use compound tables that require all five axis of motion for each feature. When a part springs out of shape, then it is nearly impossible to use compensating offsets with accuracy. A better method is to use a "B" and a "C" axis, and then position to grind in just 2-3 axis, allowing for simplified offsets. With the latter axis configuration, then Machine Application Visual Interface Software (MAVIS) can be used to input offsets to compensate for spring detected by the CMM, without stopping production to wait for a programmer.

Reliability

Lastly, all this technology is for naught if the machine is not dependable. When it is down for service, it is not producing. But, long-term application of ISO 9000-2000 (2008) standards in manufacturing, and modular machine designs are yielding warranty claims in the 0.1’s of percentages and true machine uptimes of +99%.

ISO standards require more in-depth, pre-order customer collaboration to address actual end-product and process requirements that can be designed into the machine tool. Base designs can minimize thermal distortions, and chillers maintain grinding thermal excursions to 1 degree. Rotary axes can be designed for zero backlash. Linear axis can be mapped for accuracy.

Modular machine designs allow customized envelop configurations from standardized components that reduce costs, increase flexibility, and lower downtime. Mechanical causes of machine downtime can be virtually eliminated.

Confluence of factors

This confluence of factors has resulted in significant improvements in individual-part processing quality, productivity (faster delivery), cost, and asset utilization that cumulatively create outstanding economic results. For one recent conversion of an aerospace component from a conventional grinding process to a 5-axis, CBN process, a five-times productivity was achieved. That amounts to an 80% reduction to cost, prior to the asset reduction to inventory, and reduction of floor space and capital requirements that also leverage return on investment.

Technological advances don’t improve product quality, if a machine is not dependable. Consistent application of ISO 9000 quality standards, applied with modular machine designs, reduces warranty claims and increases machine uptime.

These factors are ushering in extraordinary levels of competitive advantage, favorably altering the economics of the entire industry. Individually and collectively they create technical equalizers to offset the cheap labor, long supply lines (inventory), poor response, and confusing communications from distant manufacturing locations. Together, these factors provide a compelling economic reason to invest in a down market, to lower cost in the short term, and to position for economic dominance in the upturn.

Roger H. Hayes is president of Huffman Corp., a manufacturer of multi-axis superabrasive grinding systems, multi-axis laser drilling, cutting and powder fusion welding systems, and multi-axis precision abrasive waterjet systems.