Solving the Rattling Bearing Problem in Spindles

Machine tool spindles serve as the backbone to numerous manufacturing sectors, enabling creation of precision-engineered components with exceptional accuracy. However, there is a persistent problem at work these critical parts: noise and vibrations originating from ball bearings. Ball bearings are essential elements in spindle design, but they are prone to generating disruptive noise and vibrations that can significantly impact spindle performance, quality, and operational efficiency.

More particularly, one of the primary challenges is the occurrence of a sudden and strong increase in noise, often called rattling or squealing noise in the industry, which generates vibrations and can be both alarming and disruptive to the machining process. Surprisingly, this kind of noise is hard to predict and can occur unexpectedly even when the spindles have new bearings installed.

Furthermore, the noise is not limited to high-speed operations, as it can also manifest at lower speeds. Also, the bearing spindle can rattle like crazy even under the lightest loads, exacerbating the issue. This unpredictable and disruptive noise occurrence poses significant challenges that necessitate thorough investigation and innovative solutions to maintain the smooth operation and performance of machine tool spindles.

Unfortunate consequences, unsatisfactory solutions

The rattling noise can have significant consequences that affect both productivity and operational efficiency. One possible consequence is the increase in machine tool downtimes. When the noise becomes pronounced, it may necessitate shutting down the machine for investigation and repairs, leading to undesirable delays in production schedules.

Moreover, the occurrence of such noise demands more maintenance efforts and constraints. In some cases, this may even require the replacement of (relatively) new bearings!

Furthermore, the repercussions extend beyond the manufacturing process, potentially leading to postponed customer technical acceptance or even end-customer claims.

The uncertainty associated with the noise problem, as it may occur intermittently, adds an element of unpredictability and unwanted costs. Additionally, it is crucial to acknowledge that the noise has also an impact on operator well-being.

To cope with the rattling noise in machine tool spindles, the general recommendations often emphasize the importance of proper maintenance practices. Regular inspection, lubrication, and alignment checks are highly recommended to identify and address any potential issues before they escalate into a more significant problem.

Additionally, replacing the bearing, even if it is relatively new or almost new, is sometimes suggested as a potential solution. However, despite these recommendations, it is worth noting that these solutions may not always be satisfactory. In some cases, even after following rigorous maintenance practices and replacing the bearings, the rattling noise may persist or still occur later, leading to frustration and ongoing challenges. This indicates that the underlying causes of the noise may be more complex and require a new approach to achieve a long-lasting solution.

The cage instability phenomenon

Despite ongoing efforts, the persistent challenge of finding a solution to the rattling noise problem remains. One of the primary reasons for this is the poor understanding of the underlying phenomenon itself. Its elusive nature made it challenging to pinpoint the exact causes and develop an effective resolving strategy.

Moreover, the fact that the noise appears randomly adds another layer of difficulty. In fact, it was even difficult to provide a definitive name for this specific noise.

The problem has a name: the phenomenon of cage instability.This is a well-known and documented phenomenon outside the manufacturing sector: In space engineering, for instance, at the level of gyroscopes or reaction wheels. The phenomenon has remained without solutions for several decades. Until now.

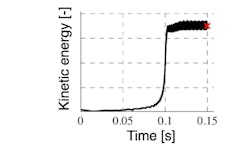

The cage instability phenomenon involves a sudden and significant increase in the kinetic energy of the cage, which results in an abrupt and pronounced disturbance. The energy involved in this phenomenon is exceptionally high, causing a “hula hoop” movement of the cage, also called cage whirl. Remarkably, the speed of this whirl can reach up to one-hundred times the rolling speed of the bearing.

What sets this phenomenon apart is its distinct ‘On/Off’ characteristic, differentiating it from the gradual noise generated by normal bearing degradation. In the same way that this behavior was difficult to predict and characterize for space applications, it was also difficult to apprehend in the context of machine tools. Once again, until now.

Many parameters have an impact on the cage instability, so a small change in the geometry and/or in the working conditions can change a good cage into a bad cage. The cage stability can be compared to that of a tightrope walker. With conventional bearing designs, it is as if the path to stability is extremely narrow. It doesn't take much for the walker to fall into the void or the bearing to tip it into instability.

It is important to mention that instability should not be confused with other phenomena. A well- conducted frequency analysis for instance shows that the phenomenon of instability generates characteristic frequencies. These ones are very different from the typical failing frequencies associated to ball bearings (ball pass frequencies on both inner and outer races, ball spin frequency and fundamental train frequency). And with far greater powers.

A new, unconditionally stable cage

While the current solutions for limiting noise and vibrations in ball bearings for machine tool spindles have limitations, a real breakthrough has been made. Through a comprehensive understanding of ball bearing kinematics, an innovative approach, and original computational modeling tools, the mechanisms that govern cage instability have been precisely discovered. This has proven pivotal in finding a concrete solution: the Butterfly cage, a new, unconditionally stable cage for which a patent is pending.

For the first time it is possible to explain what we hear from of a machine in a situation of rattling or squealing noise, or what we see on frequency analysis. For the first time, it is possible to have a truly appropriate solution. If we take the analogy of the tightrope walker again, a bearing equipped with a Butterfly cage no longer evolves on the rope of instability: it has a highway of stability in front of it.

The solution, which consists in enhanced bearings, is robust, directly applicable, and does not require any changes to the spindle assembly.

The knowledge has been validated both mathematically and experimentally. The unconditionally stable cages have been validated for aerospace applications, for which the operational conditions are even more restrictive than those of machine tools.

By harnessing deep understanding of ball bearing physics and the phenomenon of cage instability on the basis of more than 12 years of intensive research, a concrete solution has emerged to solve the problem of noise and associated vibrations in ball bearings for machine tool spindles. This breakthrough not only enhances the performance of machine tool spindles but also sets a new standard for precision engineering.

Christophe Servais, Ir, PhD, the Chief Technology Officer and co-founder of APO-GEE, is a Mechanical Engineer who holds a PhD in Applied Sciences. His research primarily focuses on studying the behavior of ball bearings that operate at high speeds and/or in harsh environments, such as those encountered in space applications, machine tools, or dental applications.

About the Author

Christophe Servais

Chief Technology Officer

Christophe Servais, the Chief Technology Officer and co-founder of APO-GEE Engineering srl, is a Mechanical Engineer who holds a PhD in Applied Sciences.