Machine Tool Orders Fall Below 2021

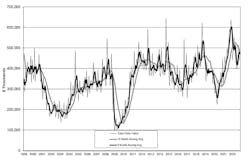

U.S. manufacturers’ new orders for machine tools slipped for the second consecutive month in November, down -4.5% from October to $425.28 million, and down -31.5% from the total posted for November 2021.

The new figures bring the year-to-date total for machine tool new orders total to $5.1 billion through November, which is -3.7% less than the January-November 2021 result. It is the first time this year that the YTD total lags the 2021 figure.

The data is supplied by AMT – the Assn. for Manufacturing Technology in its latest U.S. Manufacturing Technology Orders report. USMTO summarizes monthly totals of nationwide and regional demand for metal-cutting and metal-forming and -fabricating machinery.It is a forward-looking indicator of overall manufacturing activity, as machine shops and other manufacturers make capital investments in preparation for demand expected in the weeks and months ahead.“After recording the highest level of orders in 2021, it was only a matter of time before 2022 fell slightly behind,” said Douglas K. Woods, president of AMT. “The fact that orders stayed above 2021 levels for 10 months really speaks to the continued strength in the demand for manufacturing technology. This demand has been spurred by the extraordinary economic challenges of the last few years, which has prompted expanded domestic manufacturing as well as foreign direct investment.”

The November report shows the growing effect of rising interest rates on the domestic economy, in particular on manufacturing sectors linked to home construction and renovation. Manufacturers of household appliances have continued to reduce their orders, AMT noted, and similarly declining investments are evident in the HVAC and commercial refrigeration sectors which are more closely related to commercial construction activities.

Job shops remain the largest customer segment tracked by the USMTO report, though job-shop new orders peaked in September 2022. AMT noted that “the average value of orders from job shops has been increasing, indicating continued demand for the more-automated, higher-value machinery. Order activity in this sector appears driven by application-specific needs rather than expanding capacity.”

The November report’s regional results showed new orders for metal-cutting equipment were strong in the Northeast (+12.1%) and the North Central-East (+19.7%), the only two of six regions to post improved order volumes from October. Each of the six regions posted double-digit declines in order volumes versus the November 2021 results.

“Despite some of the slowing orders, a number of our members remain confident in their 2023 projections because of the outstanding orders collected in 2022,” according to Woods. “2023 will most likely be a balancing act. The manufacturing that has returned to the country will continue to spur economic activity, which may be tempered by rising interest rates and slowing demand.”