Surface Treatment That Improves Machining and Cutting

It’s a strange-but-true fact about machining that hard metals (like iron and steel) can be simpler to work with than softer materials (like aluminum), which often produce “gummy” swarf that impedes the work of a drill or cutting tool. Purdue University researchers report they have developed a way to resolve the issue -- and their discovery may help machinists improve their work and reduce process failures.

Researchers at Purdue Research Foundation Office of Technology Commercialization previously reported that that applying permanent marker (e.g., Sharpie), glue, or adhesive film made it easier to cut aluminum, stainless steels, nickel, copper, and tantalum, or other metals for industrial applications. Marking the metal surface to be machined with ink or an adhesive dramatically reduced the force of cutting, leaving a clean cut in seconds.

Now, they have reported how these films produce the effect. If a significant improvement can be made to the machinability of gummy metals or alloys – that is, how well they cut, drill or grind – then there is potential to lower the cost of products, improve their performance, or enable new and improved product designs.

“We have found that you only need the organic film from the markers or glue to be one molecule thick for it to work,” stated Prof. Srinivasan Chandrasekar, of Purdue’s School of Industrial Engineering. “This ultra-thin film helps achieve smoother, cleaner, and faster cuts than current machining processes. It also reduces the cutting forces and energy and improves the outcomes for manufacturing across industries such as biomedical, energy, defense and aerospace.”

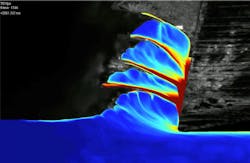

The researchers found, using organic monolayer films created by molecular self-assembly, that the molecule chain length and its adsorption to the metal surface are key to realizing these improvements. By using the “right” organic molecules, the metal is locally embrittled, which results in improved machining.

“We are also learning through our discovery more about how environmental factors influence failure of metals,” said Anirudh Udupa, a lead author on the study and a researcher in Purdue's School of Industrial Engineering. “As we decipher how the organic molecular films improve the machinability of these metals, the better also is our understanding of common environment-assisted failures in metals, such as stress-corrosion cracking, hydrogen embrittlement, and liquid metal embrittlement.”

The collaborative research involved researchers at Japan’s Osaka University and the Indian Institute of Science, with support from the National Science Foundation and U.S. Department of Energy. The results are published in Science Advances, an open-access scientific journal.

The Purdue researchers worked with the Purdue Research Foundation Office of Technology Commercialization to patent this technology, and are seeking partners to continue the development. For more information, contact OTC at [email protected] and reference track code 2019-CHAN-68634.