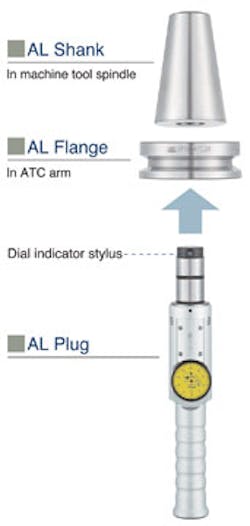

When automatically loading a tool holder, any misalignment of the ATC gripper to the spindle may cause damage to the spindle taper. A misaligned, clamped tool holder will lead to increased runout, shortening the life of the machine tool, cutting tool, and tool holder. The BIG Kaiser ATC alignment tool helps operators to avoid this problem by making sure the ATC gripper aligns the tool with extreme precision — preventing any collision and potential damage. The tool may also be used to align the ATC gripper to the magazine tool pockets.

The ATC alignment tool joins BIG Kaiser’s range of machine inspection, installation and repair technologies, which includes the Dyna Test, Dyna Force, and Level Master devices. BIG Kaiser Precision Tooling develops high-precision tooling systems, including the Kaiser, BIG Daishowa, Speroni, Unilock, Sphinx, and other brands.

The tool is designed with a built-in stylus that determines the high/low values when the plug is slowly rotated. The values are displayed on a 10 micron/div. dial indicator and reveal the eccentric direction—half of the gap between the high and low is the eccentric amount. Such eccentricities would be otherwise imperceptible.

“The ATC alignment tool functions as a preventative maintenance tool for operators, but also is useful during repairs, and even during the original machine and tool magazine setup,” according BIG Kaiser vice president Jack Burley. He called it “an indispensable accessory” for machine tool repair and installation technicians.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.