Small-but-Powerful Rotary Indexer

Machine tool builder Hardinge Inc. says its new GD5C2 rotary indexer “packs a big punch,” despite its small footprint. And, it follows more than a century of collet products designed with precision and reliability.

The new indexer weighs only 55 pounds, so it can be installed without a hoist. Inside its small frame, the designers point out, “are dynamic mechanics that deliver precision parts 24-hours per day in a thoroughly-sealed system that keeps coolant out and lubricant in.” This includes a robust, dual-bearing spindle that accommodates heavy radial and axial loads increasing overall indexing capabilities. A part weighing 50 lb (23 kg) and tailstock thrust of 500 lb (2224 N) per spindle is not a problem – even on a quad unit with tailstocks.

Next, the spindle, worm drive shaft, and cross-axis helical gear are machined on a “super-precision” Hardinge lathe and finish-ground for high accuracy and repeatability.

Double eccentrics provide fine gear mesh adjustment that extends service life and improves accuracy over time. The Hardinge GD5C2 has a standard maximum run-out length of two-tenths total indicator reading. Final inspection is performed using a Heidenhain encoder mounted directly on the spindle nose to ensure final positioning accuracy and repeatability. To back up the inspection, a printout of accuracy is shipped with each product.

The GD5C2 indexer can be used to position parts for milling, drilling, tapping, contouring, engraving, grinding, welding, assembly and automation. It occupies so little space that it can be mounted along with other clamping devices on the machine bed. On the spindle, the indexer’s extended spindle nose, curved front casting and removable handle provide good tooling clearance.

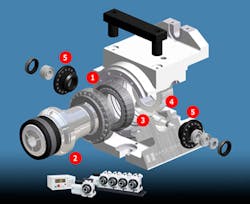

The new Hardinge GD5C2 design includes 1) a dual-bearing spindle for heavy radial and axial loads; a 2) spindle; 3) worm drive shaft; 4) cross-axis helical gears; and 5) double eccentrics for fine gear mesh adjustment.

The standard indexer package uses the Hardinge all-digital servo control. Features include infrared program upload capability and storage capacity for up to 50 programs (each with up to 1,000 steps). The multiple-line display will show large amounts of data without scrolling. The two cables on the indexer connect to the servo control and the servo control plugs into a grounded AC receptacle. Other servo control options include the use of an RS-232 interface, a CNC interface cable using M-codes or a combination of both. The indexer is most productive as a true fourth-axis. In this case, the indexer is directly connected to the machine, fully operating with the other axes without the use of the servo control.

The Hardinge GD5C2 rotary indexer is industry compatible for drop-in replacement with fast 360° per second indexing speed. The Hardinge design incorporates a high-precision collet-ready spindle that adds gripping flexibility to the package. Collets, step chucks, expanding collets and manual jaw chucks can be used with a collet closer. This allows a wide variety of gripping options to handle most part sizes, shapes and materials.