Pinpointing The Cutting "Sweet Spot"

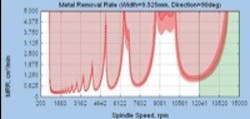

Trying to find that elusive optimal combination of spindle speed (rpm) and axial depth-of-cut by trial and error for a given tool and material is a little like looking for a needle in a haystack. But a dynamic analysis technique is available that is designed to pinpoint the optimal cutting parameters of spindle speed and depth-of-cut for a specific tool/toolholder/machine stackup to maximize metal-removal rate while avoiding chatter. The technique is mainly used for milling, boring and turning operations with aluminum, cast iron, steel and high-temperature alloys. It's available from Manufacturing Laboratories Inc. (www.mfglabs.com) and its Midwest technical support provider D3 Vibrations Inc. (www.d3vibrations.com)

"Machine tool users do not know the performance characteristics of their machines and frequently under utilize them," said Dr. David Dilley, owner of D3 Vibrations. "Using the techniques [his company developed] we typically improve overall shop metal-removal rates by 30 percent over those obtainable with conventional techniques. The instrumentation optimizes cutting parameters in minutes when it would take customers weeks to years, if ever. The software dispels many myths of milling."