Business “uncertainty” has been challenging the managers and executives of virtually every organization during the past year, or even longer. The best of them address these challenges by emphasizing their businesses’ core functions.

Tech businesses are seeking new concepts and functions to break through methods currently in use by designers, manufacturers, and consumers. Manufacturers are striving to remain consistent with the irregularities of their supply chains and the shifting requirements of their markets. And suppliers and distributors are stretching their resources and capabilities to deliver what the consumers need and want.

As a cutting-tool developer Sandvik Coromant is a tech firm, a manufacturer, and a supplier – and as the president of the organization since 2020, Helen Blomqvist recognizes her responsibilities range from raw materials to the composition and shapes of individual inserts at the ends of thousands of CNC machine spindles worldwide.

Blomqvist’s experience is grounded in research, as she recounted in an interview last fall, but she has been keen to involve herself in other dimensions of the business since joining Sandvik Coromant nearly 20 years ago.

--- --- ---

How did you come to be leading a cutting-tool design and manufacturing firm?

“It feels like I have been growing up with this company. I started in 2003, so next year it will be 20 years. And while I have quite a broad background now, I started as an R&D engineer. My background is in R&D, and materials research.

“I have a PhD in chemistry, and I really wanted to join Sandvik Coromant, because I knew that they had a really good R&D facility for materials research in Stockholm. So it was really, you know, kind of a dream, to join the team. So that's where I started.

“To be honest, I didn't really have ambitions to lead the company one day; that was not really in my mind. I was enjoying my time in R&D, and doing a lot of great research and product development, and then leading different teams and becoming more experienced from the leadership perspective. And then in 2015 I made a change and went into sales, and that was fantastic, because I really think it's super fun and value-creating to be close to the customers.“You know, having been more in the back end, in R&D, suddenly I got to see how the products were used, how we were perceived as the brand, from the customers’ perspective. So I really enjoyed that – as well as working very close to our production operations during all these years.”

So, you gained different perspectives as your assignments changed?

It has been evolving, I would say and just, you know, having bigger and bigger responsibilities. And then I was also part of the Sandvik Coromant leadership team for a while as the vice president of product management and R&D. And then this opportunity (as president) came ... And you know, I'm truly passionate about the company. So, of course, to lead the company would be a great honor, I thought, and I was really happy to actually to get the opportunity to do that, and the confidence and the trust as well.”

It seems more of a straight line, as you tell it, than I imagine it seemed to be in the process.

I mean, it's been a little bit back and forth, but I had so many great leaders and managers within Sandvik Coromant that have truly believed in me and they had been pushing me, giving me new opportunities.

The fact is as well, of course, you need to be curious and dare to take on bigger responsibilities, but also that you need to deliver. You need to work hard, you know, and also be passionate about what you do. And always strive to upskill yourself and learn more. So I think that when you're curious, and you get an opportunity and you just jump: Yes, let's go for it! Even though it might be outside of your comfort zone. Going into sales – that was not my comfort zone. But that's turned out very well.”

Does R&D hold more precedence because of the need for information, and development of design, and proprietary control? Or does the market have more influence, shaping the direction of Sandvik Coromant?

“It's a very good question. I think it's a little bit of both. I mean, we invest more than double that of any other manufacturer in our industry in R&D. We want to reinvest money in that area, of course.

“The answer is that it's both. R&D and the customers’ needs are both top priorities. What the customers need and our own curiosity for their problems need to guide the R&D organization.

“But there are also some parts that need to come from within, you know, a kind of strong innovation where we also discover things that the customer doesn't expect.

“So I think there we must have an inner driving force, more R&D driven: ‘What is achievable? What can we actually accomplish? What can we do, and what could actually change the manufacturing world?’ … more visionary.

“But then there is the biggest part – driven by the customer’s need. This is a balance we need to be careful about because it's always the customer’s needs that drive what we put in the marketplace.”

Do user groups have any role in these developments?

“Absolutely. And more and more.

“We are doing something of an ‘agile transformation’ in Sandvik Coromant… going more from a waterfall organization and more into an agile set-up.

(Editor’s note: “Agile transformation” is a managerial concept that describes gradual revisions so that an organization can adopt new goals and become flexible, collaborative, self-organizing, and quickly adaptive.)

“And of course, to be more agile, to be fast, to have use cases to work with user groups, and with the product teams that we have, that's a much faster way of understanding the markets, getting feedback fast and really developing and going faster.

“Especially now when we are also active in the software industry, Sandvik Coromant is becoming more and more complex in our offer. The portfolio is getting bigger and bigger. So it's one thing to develop an insert and you know, with our experience, we pretty much know what the customer is looking for.

“But for sure, when you then explore and expand your offer, and you add digital solutions, and add on design support, and so on, those are different kinds of customer problems that we’re solving. And so to have user groups, and also to talk more to focus customers as well, and develop together with them, is truly important. That speeds up innovation

Is there any value to customization, as in developing particular products for customers in particular markets, e.g., in aerospace?

“Absolutely, that's where our knowledge comes into play. Of course, a lot of our assortment and what we sell is standard but we have continuously developed our offer, so as a customer you can order on the web, and you can modify the standard tool a bit yourself, as we call ‘tailor-made,’ but that's not a fully customized solution.

“For ‘customized’, you also have engineering support, design support, manufacturing in fast feedback loops – those are things that we have been doing for many years – and as we are going into the market segments defined by electrification and aluminum machining, this is becoming even more important.

As you mentioned electrification, there is a new series of parts to be machined, some known materials, but also some unknown materials, and the scale of this market is a very difficult thing to forecast. How is Sandvik Coromant approaching that?

“ Well, I think we have to go a little bit back in the history. Already in 2010, we started to see that shift in the automotive sector, because a big part of what we do with Sandvik Coromant is to talk to the customers, and study global trends.

“Of course, with this shift in automotive, we understood that aluminum will become a more important material to be machined. So, we started to build our competence in 2010, and we are continuing to build up this bit slowly. And also, we have partnerships. We have built up our production capabilities because many of these tools need to be reconditioned as well.

“So there are a lot of different capabilities that we need as we’re entering the electrification and EV market. Even if we started on this some time back, we need to consider the acceleration of the shift, too.

“Apart from doing all this in-house, we have also been quite focused in our approach to acquisitions. So recently, we acquired Preziss, a Spanish company, that is very capable in in this area.

“So we are taking it step by step, and we are winning more and more projects in this area.”Have you identified market segments where Sandvik Coromant will pull back as they become less valuable?

“I would say no, but everything goes a little bit back and forth. You know, there are many segments now that are growing much more than they did before. This is a constant process.

“We need to be agile and flexible on how we work with our resources, and with the competence we have. But of course, automotive and aerospace for us are important segments and will continue to be so – but these can be broken down into sub segments that have pockets of more growth, depending upon how the world is looking. Some of them are standing still more and some are growing more.

“But one area where we see growth potential is with the solid round tools. So here, we are also acquiring more companies to complement our offer.”

What's the role of digitalization in tooling design?

“I would say ‘everything,’ because digitalization is so big. I mean, it's also about how we support the customer in the whole manufacturing value chain. Recently, we acquired CGtech and ICAM to expand our offer.

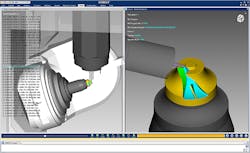

“In the design and planning phase in combination with verification and optimization software, for example, CGTech’s Vericut (and other partners) we have established open integrations for post processing of the G code. There are numerous different ways of digitalization - including, you know, acquiring knowledge about the customers’ machine data, and predicting when tools need to be changed and so on.

“Digitalization is very much involved in the machining process, with sensors, but also outside the machine in the designing of parts. And afterwards, with the verification.

“So, there is a digital thread of the whole part, with which we need to be active, and we are very much active in all these areas, with internal development of own solutions, but also very much in an ecosystem of partners, learning how to really connect with everyone.”

Can you describe Sandvik Coromant’s position in regard to supply-chain strengths and/or vulnerabilities”

I will say we have been very consistent during the COVID pandemic. We have not really seen any major supply chain disturbances, thanks to a very active procurement organization and a raw material supply that is strongly connected to the fact that we recycle solid carbide.

We are very independent on raw materials, so to speak, but we have a mine in Austria for raw materials within the Sandvik Group. So, when we look at cobalt, for example, we hardly buy any virgin materials. We are very self-sufficient when it comes to supply.

“So there has been very little disturbance. This is also true in regard to energy, where we have many sustainable solutions in place, making us less vulnerable. So, things have been very stable, I would say, and we have been able to make sure to maintain deliveries to our customers. It's the flights, I would say, that have been the most challenging, flying products all over the world. That has been a bit of a challenge, but otherwise we have been pretty stable.”

--- --- ---

Uncertainty may be the defining characteristic of this era for global economics, but business leaders that remain committed to their organizations’ purpose – as is evident for Sandvik Coromant – can be confident of their progress.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.